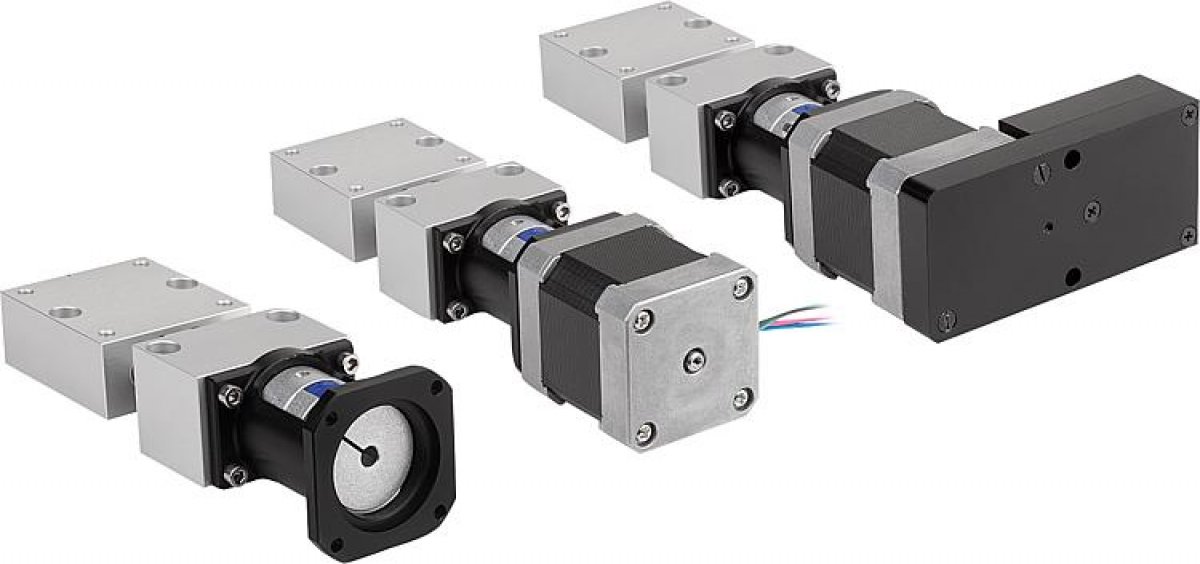

Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (25000-15).

The stepper motor with a resolution of 200 increments per rotation allows a single direction calculated positioning accuracy of 0.005 mm. The absolute single direction positioning accuracy is 0.01 mm. The system can be operated with a duty cycle of 100%.

Can be combined with all other parts of the same size.

Material:

Bearing block and carriage aluminium alloy.

Guide column and threaded spindle stainless steel.

Plain bearing for guide columns and spindle nut high-quality special plastic.

Claw coupling aluminium with polyurethane coupling spider.

Version:

Aluminium alloy anodised.

Stainless steel hardened and ground.

Threaded spindle with ball bearing.

Note for ordering:

The unit is supplied with the position of cable outlet or control unit as shown in the drawing.

Technical data:

Threaded spindle pitch: 2 mm

Axial backlash of threaded spindle: <0.04 mm

Radial play of guides: <0.02 mm

Max. input speed: 600 rpm

Max. travel speed: 20 mm/s

Max. duty cycle: 100 %

Application temperature: +10 °C to +50 °C