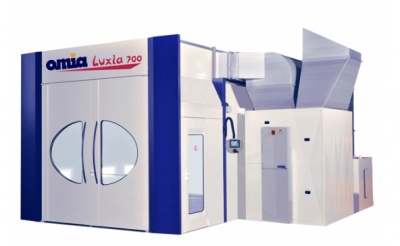

Cabin of mixed paint, spraying / steaming.

LUXIA - ENERGECO Process range.

Principle of vertical ventilation with balanced overpressure with heating.

Integrated ENERGECO process:

- Cabin time decreased by 22%.

- Reduced operating cost by 34%.

- Daily productivity increased by +1 vehicle / day.

6 major innovations associated:

- Regul'press: Regular pressure in the cabin and control of fouling provided by 4 digital sensors.

- Air Touch: interactive control unit and ergonomics completed - multi-language color touch screen with navigation icons and drop-down menu.

- Aerospeed: Optimization and directional orientation of incoming and outgoing flows (reduction of motor currents).

- Isolpax: Self-centered self-centering interlocking loudspeaker panel insulated with high-density rigid rock wool.

- Isophonia: overall acoustic treatment - less than 75 dB (A) in the cabin.

- Protect Planete: More than 90% recyclable materials and components (reduction of greenhouse emissions).

3 levels of filtration.

Automation of functions by PLC. High resolution IRC 85% - daylight type in IP54 waterproof housing with electronic ballasts.

Configuration on civil engineering or metal base (with built - in full ramp / ramp design).

Energy heating GAS direct in air vein.

Suction floor with galvanized gratings - Optimum floor suction surface.

Multiple setup combinations. Wide dimensional range.