In the small suburb of Les Ulis, south of Paris, a precision mechanics company has turned around its production strategy to start producing components for the creator of one of the most sought-after high-tech mobile speakers – the Devialet Phantom, which claims to produce ?the best sound in the world."

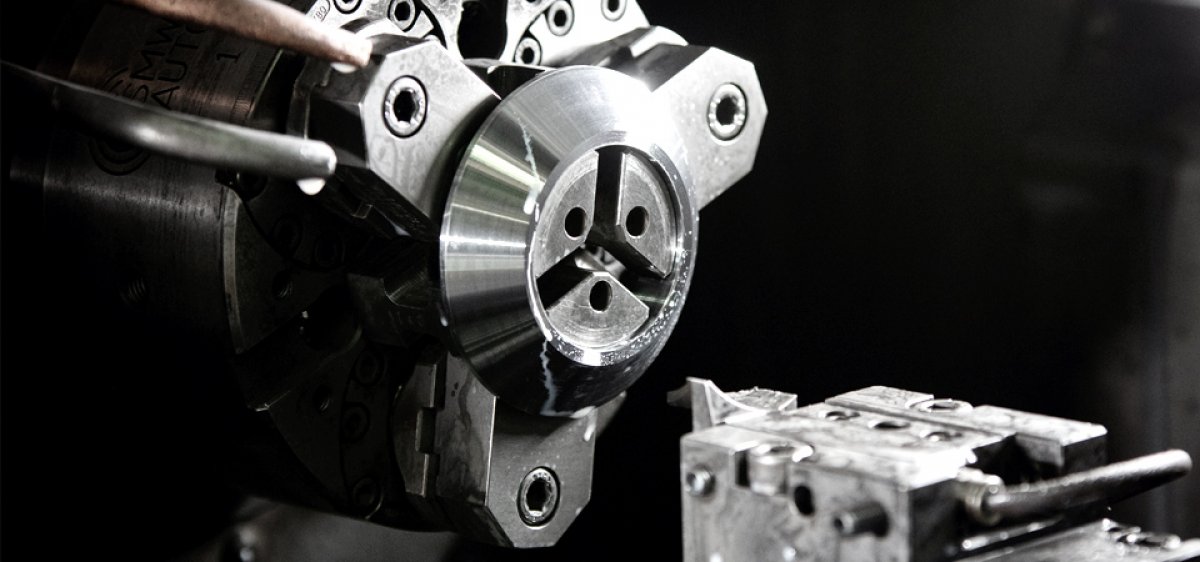

An object is the sum of its component parts, so quality matters for each part. When Devialet, a manufacturer of high-end speakers, was looking for a local manufacturer to produce a two-part magnetic driver for the woofers used in its speakers, it wanted a company that could integrate its own production schedules and respond to rigorous specifications. And that’s where Kirchheim-Grillot Industrie stepped in.

Kirchheim-Grillot Industrie has its roots in producing small batches of small mechanical pieces. ?Mass production has never been part of our business, so this new mass-production activity represented quite a shift for us,? explains Christophe Cussaguet, president of Kirchheim-Grillot Industrie. ?We were keen to tackle this new challenge, but we were aware that it wouldn’t be easy. We began discussing the project in 2016 and carried out a study at the end of that year, ordering DMG MORI machines in December. They were delivered in June 2017, installed in July, and production began in September 2017.? Kirchheim-Grillot Industrie agreed with Devialet that the arrangement would not represent more than 25 percent of the company's revenue.

Devialet also wanted to work with Kirchheim-Grillot Industrie as part of its mission to produce cutting-edge technology that is 100 percent made in France. Previously, these parts had been manufactured in China; bringing in Kirchheim-Grillot Industrie took Devialet one step closer to that goal.

?Setting up the logistics took six months, and we had to learn a lot very quickly and use a lot of imagination,? adds Daniel Kervella, head of production. ?We had to modify part of the factory to house the machines, create space to store freshly machined parts, create a logistics channel so our subcontractor could collect the pieces, paint them and bring them back, and then have the finished product dispatched in the right packaging to Devialet so it slotted immediately into their production line. This was a production chain that was new for us, and we had to learn it all,? he explains. Kirchheim-Grillot Industrie even had to commission six special skips to collect the chips produced each day. These are emptied daily by a subcontractor who recycles them into steel production, picking up some nine metric tons every week from Kirchheim-Grillot Industrie.

But the main challenge facing the smooth introduction of this new production line involved chip removal. ?We started out using standard machine tools – like everyone, we have to manage our costs – so we opted for Sandvik Coromant tools, with which we’ve had very positive experiences in the past,? explains Daniel Kervella. ?But we soon realized we were facing a problem with the face grooving. We could only produce three pieces before the chips blocked the turret rotation and we’d have to stop and clean the machine. That meant we were only operational for 15 minutes before having to stop production for five. That was unacceptable.?

Kirchheim-Grillot Industrie went back to its Sandvik Coromant rep, Laurent Blond, and explained the problem. ?When Kirchheim-Grillot told me how much downtime they were experiencing, I knew how important it was that we help them solve the problem and get them back up and running smoothly,? he says. ?Otherwise, the whole project was threatened, and they’d be forced to look elsewhere for their tools. But I knew that we had a new specialist tool for such issues currently in development, so I contacted Lionel Legrain, Sandvik Coromant’s product manager for South Europe, to see if we could come up with a fix.?

?Laurent Blond contacted me and said the project was in jeopardy and could we help,? Lionel Legrain recalls. ?We were currently testing the new CoroCut QF tool for secure face grooving, and it seemed perfectly suited to this situation, so we got to work. The tool path was relatively short, but we worked on designing a route to ensure better chip control, that wouldn’t require the constant presence of an operator and that required only one tool change daily. It was very complex because the C10 is a ductile material. CoroCut QF also has integrated cooling, which helped solve another issue Kirchheim-Grillot Industrie was having with loss of pressure in the cooling pump over the day.

??If the cutting conditions are right, the process is secure and stable, chip removal is managed and the machining times are respected, then they can cut all day, and that’s what they got,? says Lionel Legrain. ?We ended up delivering the solution to Kirchheim-Grillot Industrie six months prior to the official launch of the new CoroCut QF tool.?

?There are always issues and improvements to be made in every project,? says Christophe Cussaguet. ?Here we needed to be producing big numbers and fast. We were working with a real sense of urgency to get everything up and running. And because this was a whole new activity for us, we didn’t know what to expect in terms of the tools. Sandvik Coromant is our biggest supplier of machine tools and our only supplier for the Devialet project. They were fully on our side, very present and supportive, even sending a couple of guys over from Sweden. They knew that we’d work with their tools if we could, but that we’d go elsewhere if we couldn’t make it happen.?

Now production is fully up and running in Les Ulis, with Kirchheim-Grillot Industrie producing 60,000 two-part ensembles annually, two of which are used in each Phantom speaker. The company is now looking to produce another element for the tweeter and mid-range components in Devialet Phantom speakers, which should be validated by the end of the year. ?We have a flexibility the Chinese just can’t provide,? explains Christophe Cussaguet.

?We’re very proud of what we’ve achieved,? says Daniel Kervella. ?We managed the machining issues we were having with the help of Sandvik Coromant, but the supply chain, logistics and everything else, we put together from scratch, and that was a real achievement. The first people who needed to be convinced were Devialet, and they were very present throughout the start-up. They wanted it to work and they helped us ensure that things ran smoothly from the start. And if we couldn’t supply them for the Christmas rush, then the partnership would never have been a success.?