With its unwavering adoption of Industry 4.0 tools and analytics, such as embedded sensors and big data, Sandvik Coromant’s factory in Gimo is a shining example of how to run an efficient, standardized, yet flexible and cost-effective factory.

Sandvik Coromant’s 37-acre facility in the hamlet of Gimo, Sweden, has been in the news lately for its green initiatives and the recycling of its employee health-care equipment to the third world. But what really puts the 1,500-person-strong factory on the map is its smart and systematic adoption of digital and software technologies together with big data crunching capabilities to streamline the manufacturing processes for some 11,000 products.

Gimo is the largest facility in the world for the manufacture of cutting tools such as boring bars and cemented carbide inserts. With this new digitization initiative, Sandvik Coromant’s nine production facilities worldwide aim to save $4.4 million annually and eliminate 64,000 hours of ineffective production time, the lion’s share in Gimo.

"Full digitization is the next industrial revolution. Industry 4.0 is on everyone’s lips,? says Lars Matiasson, director of production technology tools at the Gimo facility and the person responsible for implementing IT developments on the shop floor. ?What we do in terms of process upgrades gets rolled out in eight other factories around the world, so we have to walk the talk, especially since we are a major internal customer and one of the region’s biggest tourist attractions with over 6,000 professional visitors per year."

Admittedly, Gimo’s digital voyage started more than 20 years ago. What is different today is the increased bandwidth, computing power and analytical software tools that allow machine designers and operators to implement predictive maintenance, reduce waste, forecast capacity planning and increase traceability of parts and processes, among other initiatives, to foster a lean and faster throughput.

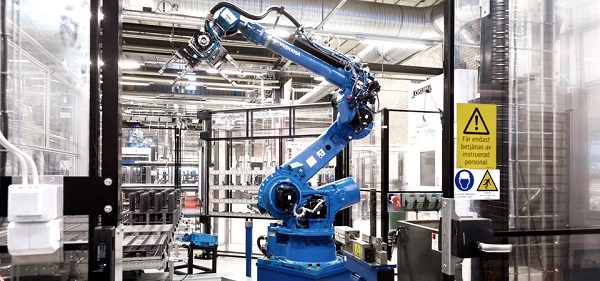

Twenty-five years ago, a cutting tool would take 54 days to manufacture from order to delivery and would include manual labor. Today, cutting tools are delivered in just under six days, thanks to an army of 40 five-axis machining centers with turning

machining centers supported by a state-of-the-art turn mill cell. There, a Yaskawa robot performs all the turning and milling on the blank bars to produce boring bars.

Today, a machine operator produces 55 percent more tools compared to 2004, thanks to improvements in predictive maintenance, fewer unplanned stops, and smarter and optimized machining and robotic cycling. Best of all, the swinging robot inside the Okuma cell reconfigures itself automatically with new collets to accommodate small and large machining orders coming from the factory’s ordering system.

"This is unique," says Matiasson. "It means that without much effort, we can tailor orders for one piece to 100 pieces without wasting time or material. Best of all, the robots do it themselves. This is customer value. No one is paying us to reconfigure the robots and the machines manually. In fact, we try not to do anything manually anymore at all."

At the moment, Matiasson and his team are implementing a five-year Industry 4.0 road map of about 23 projects to uncover possible time and cost savings in process and machining controls. This is accomplished by studying process data and implementing machine learning and other predictive systems to guarantee future production on specific machines and automated cells.

"The implementation of cyber-physical technology is the heart of Industry 4.0," says Matiasson. "The idea is to base production decisions on standard and discernible facts on a machine’s performance rather than an operator’s gut feeling about the performance of a particular machine. This is important, given that unlike previous generations, today’s young people entering the workforce will likely not stick around long enough to develop these skills over a career in one job. This workforce demographics is the reason Industry 4.0 is so important."

All in all, Matiasson and his team’s planned improvements on drilling, milling and turning operations on cutting tools are optimistic but necessary. ?Even if we reach 50 percent in five years," he says, "that is a good hit rate."

"This was not possible 10 years ago," says Matiasson.

In another project covering intelligent computer-aided manufacturing, a new software analysis NC-program is able to automatically clip away computer code governing unnecessary movements in the machines to reach time savings of 2 to 3 percent, which over a 10-year period amounts to the cost of four or five machines. Predictive maintenance can also provide enormous savings as in the CoroPlus Process Control, which is currently in place in the machining centers and is designed to react within milliseconds to, for example, save the replacement costs of a very expensive spindle.