Leader and pioneer in the FAO market, DP Technology Corp. Announces the new version of its innovative product ESPRIT®2016.

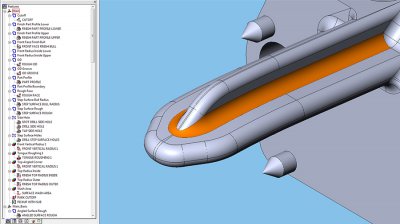

The new ProfitTurning feature combines traditional cutting strategies with trochoidal movements on the turning center.

ESPRIT 2016 presents a brand new high-speed shooting strategy, ProfitTurning ™, which complements the new ESPRIT cutting algorithms. Unlike traditional strategies based solely on part geometry, ProfitTurning ™ creates a tool path taking into account multiple machining factors and machine characteristics that increase machining performance.

"ProfitTurning ™ significantly improves chip control on hard materials such as titanium and inconel. This strategy also has the advantage of reducing irregularities in cutting forces and vibrations. It saves 50% on cycle times compared to conventional machining methods, "says Ivan Krstic, Product R & D Director.

The speed of simulation is an important criterion in FAO, and ESPRIT continues to be performing in this field, constantly accelerating its simulation speeds, while maintaining a constant precision. ESPRIT 2016 promises the user even faster previewing tools and impeccable finishing quality for his parts.

ESPRIT 2016 Advanced Tools Settings provide new solutions for programmers to manage their tools. The support of the barrel tool, extended to all 3 and 5 axis milling cycles, is unique on the market. Another major innovation is that the ESPRIT software connected to the Cloud now includes the MachiningCloud App application, which facilitates the selection of tools and enables them to be imported directly and easily into the CAM.

In addition, the ESPRIT 2016 CAD-specific recognition functions have been enhanced. They are used to detect and treat hidden defects on imported CAD models. It is now possible to modify and delete the fillets, or even to extract a curve to give an orientation to the tool in the operations. The new Hole Recognition function analyzes the different types of complex holes and renames them intelligently in order to automate their programming. ESPRIT also measures the angles of curvature of open holes to make this type of operation more precise and efficient.

The novelties of EDM software facilitate roughing. The Extra Offset option defines and proposes an additional deviation for the yarn movements, in order to reduce the additional cutting operations. The other major innovation in electro erosion, the Optimize Premier Coupe-Chute function, avoids the threading of the wire where there is no drilling intended for this purpose.

The 5 axis functions of ESPRIT 2016 have also been improved. The rolling milling cycle eliminates unwanted dive movements, and the Spiral Finishing cycle rectifies any surface defects in the part. The feed rate in the spiral blank cycle can now be accelerated during empty machining movements in order to reduce machining time. ESPRIT 2016 accelerates machining thanks to its simulation speed and state-of-the-art cutting strategies. The users gain in programming time and optimize their profits.

The new ProfitTurning feature combines traditional cutting strategies with trochoidal movements on the turning center.

ESPRIT 2016 presents a brand new high-speed shooting strategy, ProfitTurning ™, which complements the new ESPRIT cutting algorithms. Unlike traditional strategies based solely on part geometry, ProfitTurning ™ creates a tool path taking into account multiple machining factors and machine characteristics that increase machining performance.

"ProfitTurning ™ significantly improves chip control on hard materials such as titanium and inconel. This strategy also has the advantage of reducing irregularities in cutting forces and vibrations. It saves 50% on cycle times compared to conventional machining methods, "says Ivan Krstic, Product R & D Director.

The speed of simulation is an important criterion in FAO, and ESPRIT continues to be performing in this field, constantly accelerating its simulation speeds, while maintaining a constant precision. ESPRIT 2016 promises the user even faster previewing tools and impeccable finishing quality for his parts.

ESPRIT 2016 Advanced Tools Settings provide new solutions for programmers to manage their tools. The support of the barrel tool, extended to all 3 and 5 axis milling cycles, is unique on the market. Another major innovation is that the ESPRIT software connected to the Cloud now includes the MachiningCloud App application, which facilitates the selection of tools and enables them to be imported directly and easily into the CAM.

In addition, the ESPRIT 2016 CAD-specific recognition functions have been enhanced. They are used to detect and treat hidden defects on imported CAD models. It is now possible to modify and delete the fillets, or even to extract a curve to give an orientation to the tool in the operations. The new Hole Recognition function analyzes the different types of complex holes and renames them intelligently in order to automate their programming. ESPRIT also measures the angles of curvature of open holes to make this type of operation more precise and efficient.

The novelties of EDM software facilitate roughing. The Extra Offset option defines and proposes an additional deviation for the yarn movements, in order to reduce the additional cutting operations. The other major innovation in electro erosion, the Optimize Premier Coupe-Chute function, avoids the threading of the wire where there is no drilling intended for this purpose.

The 5 axis functions of ESPRIT 2016 have also been improved. The rolling milling cycle eliminates unwanted dive movements, and the Spiral Finishing cycle rectifies any surface defects in the part. The feed rate in the spiral blank cycle can now be accelerated during empty machining movements in order to reduce machining time. ESPRIT 2016 accelerates machining thanks to its simulation speed and state-of-the-art cutting strategies. The users gain in programming time and optimize their profits.