Who? ESI Group is a leading innovator in Virtual Prototyping software and services for manufacturing industries. Specialist in material physics, ESI has developed a unique proficiency in helping industrial manufacturers replace physical prototypes with virtual prototypes, allowing them to virtually manufacture, assemble, test and pre-certify their future products.

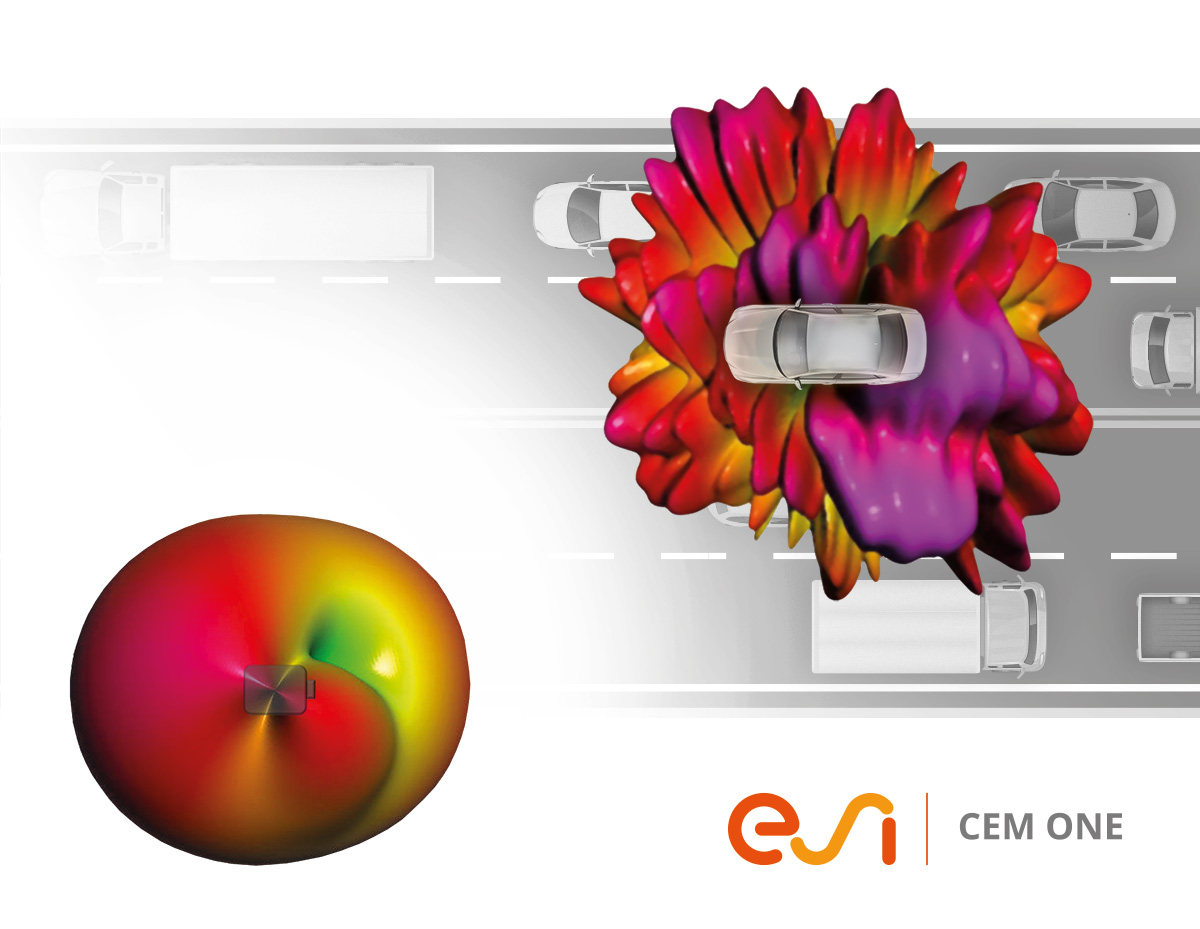

What? ESI announces the release of ESI CEM One 2018, ESI’s solution for Computational Electromagnetics. Featuring all major simulation techniques within a consolidated user environment, CEM One enables Virtual Electromagnetic Testing for fully equipped large industrial models over a wide frequency spectrum, from Radio Frequency to millimeter waves. Supporting engineers and electromagnetic experts in their daily challenge of designing electromagnetic compatibility (EMC) safe products, subsystems and systems, CEM One offers unique coupling and chaining capabilities, allowing multi-scale electromagnetic phenomena to be handled within fully realistic scenarios. As a crowning achievement of this 2018 release, emphasis has been placed on sensors integration for better performance assessment.

Mr. Yasushi Hamada, Staff Manager of the Integrated Control System Development Division at Mazda Motor Corporation comments on the latest version of CEM One: ?Compared to before, the amount of time and the number of processes has been drastically reduced using the latest version of ESI CEM One. Thanks to that, we can spend the extra time leading up to deadline on more creative ?trial and error’, instead of trivial things like data conversion. We can fulfil our duty and pursue the best product we are capable of producing to our heart’s content. During the trial period, it also reconfirmed that the ESI Group technical support is excellent.?

Driven by the race towards wireless 5G and the Internet-of-Things, the total number of connected devices should reach 50 billion within the next few years, requiring more than 200 billion sensors. Considered a key challenge for electromagnetic experts, performance assessment in fully realistic operating conditions defines the focus of the latest CEM One release with an easier sensor integration onboard fully equipped models.

This objective was achieved through two key features: an accurate modelling of printed antennas combined with an extended 3D/3D coupling capability enabling fast, easy and flexible integration. To allow a broadened usage, the optimized CEM-FD MoM solver (Method of Moments) now features a dedicated feeding module for patch antennas.

With the tremendous increase in onboard electronics in the automotive industry, internal electromagnetic environments are always more challenging. Initiated with Advanced Driver Assistance Systems (ADAS), dedicated CEM One features can be optimized in close partnership with industrial end-users to extend the performance assessment of integrated sensors to many other automotive wireless devices, as used for emergency calls, Intelligent Traffic and connected vehicles, mobility or entertainment purposes.

Similar trends are observed in the Aeronautic & Defence sector with an increase of onboard electronic devices making their EMC safe integration particularly challenging. The latest release of CEM One consolidates applications focusing on radar signature, stealth and absorbing materials through many added upgrades, featuring extended output, frequency sweep or High-Resolution range profile for target recognition and hot spots location.

Moreover, CEM One also addresses the needs of Smart Factories, with sensors at the heart of the industrial IoT solutions (Internet-of-Things), enabling machine-to-machine communication, plugged all along the manufacturing chains or installed in strategic locations of large sized plants. CEM One 2018 helps manufacturers improve data monitoring and supports them in the transformation of their factories towards smarter and safer facilities.

ESI CEM One 2018 Facilitates Integration of Sensors in Operating Environnement

InfoWeb Marketplace