Visitors to booth N68 will have the opportunity to learn of the latest innovations and approaches in Thermoforming, Compression-RTM and Sheet Molding Compound (SMC) methods, and to discover related topics in Big Data and Analytics and Machine Learning. The team will speak of its numerous collaborations with international clients and academics – including TU Dresden, for End-to-End Virtual Prototyping the AIMEN Technology Center, for Thermoplastic Composite and Metal Joining. Participants will have the opportunity to see a USCAR (Ford, GM, and Chrysler) composite element at the ESI booth and attend a live presentation on the design of a composite front bumper crush-can system using virtual prototyping. Case studies and collaborative projects that highlight the power of composites materials include:

- Electrical Vehicle gearbox demonstrator development - in collaboration with ARRK Shapers'

- Optimization of dry textiles forming for structural composite applications - in collaboration with IRT M2P

- Sheet Molding Compound (SMC) process modeling

- Chaining Manufacturing to evaluate Multi-Material Component Performance

- Accurate C-RTM (Compression Resin Transfer Molding) Modeling

Professor Maik Gude, Technische Universität Dresden (Germany); Institute of Lightweight Engineering and Polymer Technology (ILK) and Frederic Masseria, Business Development Manager Composite Solutions at ESI Group in Germany will present a new development approach for 3D hybrid structures at booth N68. They will discuss how the implementation of new composite materials in a large-scale production environment can only be achieved through the design of multi-material components and explain how ESI’s virtual prototyping simulation software allows virtual structural assessment of manufactured components.

Introducing ESI’s Hybrid TwinTM applications for the Industry 4.0

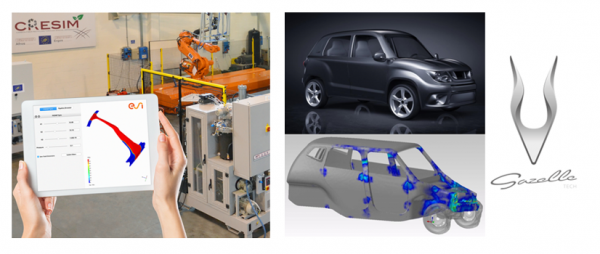

On the 1st day of the event, Professor Francisco Chinesta, President of the Scientific Committee at ESI Group will present the on-going partnership with CANNON, an international engineering solutions supplier. The Hybrid Twin™ in Composite Factory 4.0 project exploits ESI’s new vision for a complete virtual representation of a production line, replicating it in a virtual world and allowing real-time control and decision-making. Deployed for the RTM (Resin Transfer Molding) composite manufacturing chain, the Hybrid Twin™ methodology constitutes a new paradigm in simulation-based engineering sciences to support the Factory of the Future. Connecting every step of the manufacturing process ESI and CANNON collaborate to illustrate for manufacturers the power of combining pioneering technologies in System Modeling, Cloud delivery, Data Analytics, and Machine Learning.

Presenting the 1st Gazelle Tech Car Development

Gazelle Tech, a French startup created in 2014, is the first peri-urban composite vehicle manufacturer of its kind. Featuring a composite chassis and body technology that makes it one third the weight of its competition and reduces energy consumption by half, their vehicle is currently under development and the industrial version is expected to be released later this year. This innovative French company will join ESI’s booth to share their experience of using virtual prototyping to engineer and pre-certify their vehicle. As Gaël LAVAUD, CEO at Gazelle Tech commented ?ESI Virtual Performance Solution saves us time and money. We are able to validate virtually the performance of our innovative composite vehicle before even manufacturing the first real prototype?.

ESI Delivers its Smart Virtual Prototyping Solutions for Composites at JEC World

InfoWeb Marketplace