DP Technology Corp. Launches its innovative FAO ESPRIT 2015 solution, leveraging productivity and automation

Camarillo, Calif. - March 26, 2015 - DP Technology, the leader in multiple CAM innovations, is pleased to announce the release of its flagship product, ESPRIT® 2015. The solution improves productivity for all machine- Tools, generating more efficient toolpaths, and saving time with significant advances in numerical control programming. In addition to increasing productivity, this new release includes many innovations and improvements in intelligent machining, strategic machining, CAD / CAM data transfer and Cloud Connection.

Intelligent machining

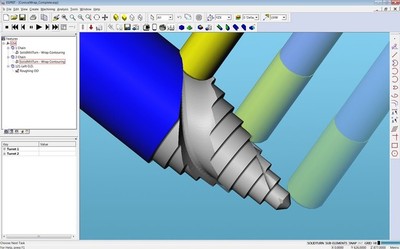

The intelligent machining functionality of ESPRIT 2015 accelerates the machining process by providing new, exclusive 5-axis cycles that reduce cycle time. It is thus possible to completely machine blades with a single assembly. The roughing tool evolves around the blade, adapting itself to the size and shape of the material, in order to compensate uniformly for the machining allowance, thus immediately following a finishing cycle.

"ESPRIT 2015 offers exclusive 5-axis functions to make complex machining more efficient. The user has more possibilities in terms of toolpaths, thanks to functions such as roughing and blade chamfering, "says Cédric Simard, Director of Marketing and Communication at DP Technology. "The design of the blades in ESPRIT 2015 makes it possible to remove material to the uniform crude around the blade, and eliminates the need for semi-finishing cycles. Programmers in the aerospace, energy, medical and automotive sectors will particularly appreciate these operations, which will save them time on precision parts. "

ESPRIT 2015 also offers the orifice roughing cycle, one as new 5-axis cycle. It creates a 5-axis blank operation to cut the material inside in areas where the tool can penetrate only through a restricted opening. The shape of the trajectory is a displacement of the surfaces of the orifice, which begins at the surface and continues inside with a constant lateral overlap.

Productivity gains

ESPRIT 2015 also includes features that improve your production. The new roughing strategy from the bottom up gives a new dimension to the ESPRIT ProfitMilling high-speed roughing cycle. This strategy achieves a low crude height during the removal process. Better yet, it can be combined with ProfitMilling, our patented high speed roughing technology, to dramatically improve overall productivity. ProfitMilling optimizes tool paths through the angle of engagement, cutting depth, lateral cutting force and machine accelerations, to drastically reduce cycle time and lengthen the life of the machine, tool.

Strategic Machining

The strategic machining capabilities of ESPRIT 2015 have been extended through the complete overhaul of the Crude Management functions for multitasking machines with milling, turning and drilling options. Available for surface milling, contouring and pocket machining cycles, the new Crude Management function stores the amount of material removed in previous operations to generate cutting passes only in areas where material remains to take off. This function greatly reduces the clearances, which considerably shortens the cycle times.

Further strategic machining improvements have been made as the new support for milling cutters in orifice and composite milling cycles. Grooving tools save time on operations such as T-slotting and shoulders, and their geometry requires less cutting effort for less resistant materials and unstable fixtures, which extends the life of the machine. 'tool.

The barrel-shaped cutters are also now supported in 5-axis blade and composite cycles. These burs provide a much better surface finish than spherical end mills because their geometry provides a wider radius of engagement and therefore more fluid paths.

CAD Transfer - FAO

The new data exchange features in ESPRIT 2015 make it easier to import CAD information into the CAM environment. Three new types of geometry - plans, profiles and curves - are now available via ESPRIT FX data exchange from Solidworks, Autodesk Inventor, CATIA, Parametric Technology Pro / ENGINEER and Siemens NX / UG. The additional information obtained from these types of geometry can be easily manipulated to cover the complex rough areas or to extend the surfaces in order to obtain a better finish on the edges.

ESPRIT 2015 provides another important improvement that shortens programming time and increases the accuracy of pattern recognition. With the new Sequence and Auto Wall functions for solid faces, loops and edges, you create strings directly on solid models. In addition, the new Wall Recognition command automatically recognizes the upper and lower limits of even tapered walls in a solid model.

FAO connected to Cloud

ESPRIT 2015 allows to select the tools according to the characteristics of the parts in a few minutes, which avoids having to go through printed catalogs to find the ideal tool. With the connection of ESPRIT to the Machining Cloud, programmers have access to up-to-date data on the tools, and reduce their programming time because they no longer have to create the tool. ESPRIT 2015 simplifies selection and automatically offers the tools you need.

Camarillo, Calif. - March 26, 2015 - DP Technology, the leader in multiple CAM innovations, is pleased to announce the release of its flagship product, ESPRIT® 2015. The solution improves productivity for all machine- Tools, generating more efficient toolpaths, and saving time with significant advances in numerical control programming. In addition to increasing productivity, this new release includes many innovations and improvements in intelligent machining, strategic machining, CAD / CAM data transfer and Cloud Connection.

Intelligent machining

The intelligent machining functionality of ESPRIT 2015 accelerates the machining process by providing new, exclusive 5-axis cycles that reduce cycle time. It is thus possible to completely machine blades with a single assembly. The roughing tool evolves around the blade, adapting itself to the size and shape of the material, in order to compensate uniformly for the machining allowance, thus immediately following a finishing cycle.

"ESPRIT 2015 offers exclusive 5-axis functions to make complex machining more efficient. The user has more possibilities in terms of toolpaths, thanks to functions such as roughing and blade chamfering, "says Cédric Simard, Director of Marketing and Communication at DP Technology. "The design of the blades in ESPRIT 2015 makes it possible to remove material to the uniform crude around the blade, and eliminates the need for semi-finishing cycles. Programmers in the aerospace, energy, medical and automotive sectors will particularly appreciate these operations, which will save them time on precision parts. "

ESPRIT 2015 also offers the orifice roughing cycle, one as new 5-axis cycle. It creates a 5-axis blank operation to cut the material inside in areas where the tool can penetrate only through a restricted opening. The shape of the trajectory is a displacement of the surfaces of the orifice, which begins at the surface and continues inside with a constant lateral overlap.

Productivity gains

ESPRIT 2015 also includes features that improve your production. The new roughing strategy from the bottom up gives a new dimension to the ESPRIT ProfitMilling high-speed roughing cycle. This strategy achieves a low crude height during the removal process. Better yet, it can be combined with ProfitMilling, our patented high speed roughing technology, to dramatically improve overall productivity. ProfitMilling optimizes tool paths through the angle of engagement, cutting depth, lateral cutting force and machine accelerations, to drastically reduce cycle time and lengthen the life of the machine, tool.

Strategic Machining

The strategic machining capabilities of ESPRIT 2015 have been extended through the complete overhaul of the Crude Management functions for multitasking machines with milling, turning and drilling options. Available for surface milling, contouring and pocket machining cycles, the new Crude Management function stores the amount of material removed in previous operations to generate cutting passes only in areas where material remains to take off. This function greatly reduces the clearances, which considerably shortens the cycle times.

Further strategic machining improvements have been made as the new support for milling cutters in orifice and composite milling cycles. Grooving tools save time on operations such as T-slotting and shoulders, and their geometry requires less cutting effort for less resistant materials and unstable fixtures, which extends the life of the machine. 'tool.

The barrel-shaped cutters are also now supported in 5-axis blade and composite cycles. These burs provide a much better surface finish than spherical end mills because their geometry provides a wider radius of engagement and therefore more fluid paths.

CAD Transfer - FAO

The new data exchange features in ESPRIT 2015 make it easier to import CAD information into the CAM environment. Three new types of geometry - plans, profiles and curves - are now available via ESPRIT FX data exchange from Solidworks, Autodesk Inventor, CATIA, Parametric Technology Pro / ENGINEER and Siemens NX / UG. The additional information obtained from these types of geometry can be easily manipulated to cover the complex rough areas or to extend the surfaces in order to obtain a better finish on the edges.

ESPRIT 2015 provides another important improvement that shortens programming time and increases the accuracy of pattern recognition. With the new Sequence and Auto Wall functions for solid faces, loops and edges, you create strings directly on solid models. In addition, the new Wall Recognition command automatically recognizes the upper and lower limits of even tapered walls in a solid model.

FAO connected to Cloud

ESPRIT 2015 allows to select the tools according to the characteristics of the parts in a few minutes, which avoids having to go through printed catalogs to find the ideal tool. With the connection of ESPRIT to the Machining Cloud, programmers have access to up-to-date data on the tools, and reduce their programming time because they no longer have to create the tool. ESPRIT 2015 simplifies selection and automatically offers the tools you need.