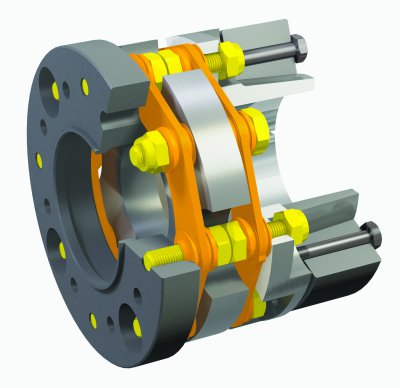

ROBA®-DS shaft couplings free from play and resistant to torsional deformation for dynamometer measuring flanges

Shaft couplings are essential components for flange torque meters in test benches because they reliably compensate for tree alignment problems. They guarantee precise measurement results and protect the bearings installed in the shaft line against wear. Mayr® offers compensating couplings based on the proven ROBA®-DS range free of play and resistant to torsional deformation, specially adapted to the strict requirements of flanges.

Increasingly shorter development times, higher yield requirements or higher energy savings potential ... The demands on test benches are getting higher every day. Therefore, performance criteria for flanged torque meters are more stringent, as these components are at the heart of modern test benches, which must provide reliable and accurate data, including high performance and high speed applications. However, the result of the measurements depends on the compensation coupling of the shaft alignment problems used because the shaft couplings are of decisive importance in limiting the disturbance variables affecting the measuring flange.

These variables often occur due to misalignment in the drive train. This is why problems of radial, angular and axial alignment occur in almost all applications between input and output. Even an extremely precise alignment of the shaft line with advanced laser equipment provides only relative help. Moreover, alignment problems can not be totally eliminated, due to the existing tolerances in the measurements of the components used and external factors such as temperature. Therefore, compensation couplings for shaft alignment problems resistant to torsional deformations are used in conjunction with the measuring flange. The mayr® ROBA®-DS compensation couplings are specially adapted to the particular requirements of modern measuring flanges.

High performance and no play

The ROBA®-DS all-steel couplings compensate for the radial, axial and angular alignment problems of the shafts. This guarantees precise measurement results and protects the bearings installed in the shaft line against unnecessary loads and thus against unexpected downtimes and costs. With the ROBA®-DS couplings, the nominal torques shown in the catalog can be used without restriction. No reduction in nominal torque due to offsets, load complexes or balancing requirements is required. The couplings are compact and combine high performance with no play. They transfer the torques to the nominal torque without play and with a constant resistance to torsional deformations. The indicated shaft alignment problems can be used in total at 100% without affecting the transmissible torque.

Adapted to test bed requirements

The couplings are particularly robust and durable and, in addition to their quiet operation and low mass inertia, benefit from an important balance. In this way, the standard versions of the ROBA®-DS couplings cover, depending on the version size, speeds between 8,000 and 18,000 rpm and have a balance of G 2.5 (at one speed Of 3,000 rpm). For high-speed versions, on which each part is produced with high precision (IT5 quality) and reduced tolerances in terms of sail and shaft play, speed values ??up to 30,000 rpm are possible . The coupling balance is G 2.5 at a reference speed of 5,000 rpm.

The connection of the ROBA®-DS couplings and the measuring flanges to the shaft line is generally free of play via high-quality conical ring hubs. The different coupling versions specially adapted to the different test bench criteria and the combination possibilities also make it possible to integrate measuring flanges to almost all types of test benches and drives.

Shaft couplings are essential components for flange torque meters in test benches because they reliably compensate for tree alignment problems. They guarantee precise measurement results and protect the bearings installed in the shaft line against wear. Mayr® offers compensating couplings based on the proven ROBA®-DS range free of play and resistant to torsional deformation, specially adapted to the strict requirements of flanges.

Increasingly shorter development times, higher yield requirements or higher energy savings potential ... The demands on test benches are getting higher every day. Therefore, performance criteria for flanged torque meters are more stringent, as these components are at the heart of modern test benches, which must provide reliable and accurate data, including high performance and high speed applications. However, the result of the measurements depends on the compensation coupling of the shaft alignment problems used because the shaft couplings are of decisive importance in limiting the disturbance variables affecting the measuring flange.

These variables often occur due to misalignment in the drive train. This is why problems of radial, angular and axial alignment occur in almost all applications between input and output. Even an extremely precise alignment of the shaft line with advanced laser equipment provides only relative help. Moreover, alignment problems can not be totally eliminated, due to the existing tolerances in the measurements of the components used and external factors such as temperature. Therefore, compensation couplings for shaft alignment problems resistant to torsional deformations are used in conjunction with the measuring flange. The mayr® ROBA®-DS compensation couplings are specially adapted to the particular requirements of modern measuring flanges.

High performance and no play

The ROBA®-DS all-steel couplings compensate for the radial, axial and angular alignment problems of the shafts. This guarantees precise measurement results and protects the bearings installed in the shaft line against unnecessary loads and thus against unexpected downtimes and costs. With the ROBA®-DS couplings, the nominal torques shown in the catalog can be used without restriction. No reduction in nominal torque due to offsets, load complexes or balancing requirements is required. The couplings are compact and combine high performance with no play. They transfer the torques to the nominal torque without play and with a constant resistance to torsional deformations. The indicated shaft alignment problems can be used in total at 100% without affecting the transmissible torque.

Adapted to test bed requirements

The couplings are particularly robust and durable and, in addition to their quiet operation and low mass inertia, benefit from an important balance. In this way, the standard versions of the ROBA®-DS couplings cover, depending on the version size, speeds between 8,000 and 18,000 rpm and have a balance of G 2.5 (at one speed Of 3,000 rpm). For high-speed versions, on which each part is produced with high precision (IT5 quality) and reduced tolerances in terms of sail and shaft play, speed values ??up to 30,000 rpm are possible . The coupling balance is G 2.5 at a reference speed of 5,000 rpm.

The connection of the ROBA®-DS couplings and the measuring flanges to the shaft line is generally free of play via high-quality conical ring hubs. The different coupling versions specially adapted to the different test bench criteria and the combination possibilities also make it possible to integrate measuring flanges to almost all types of test benches and drives.