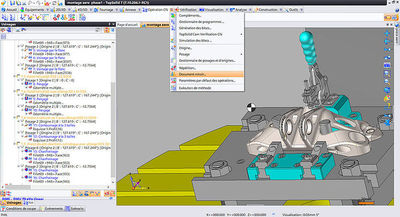

TopSolid'Cam 7.10 exclusive on the Industry Fair

The French software publisher Missler Software has just launched its newest version of its CAD / CAM software, TopSolid'Cam 7.10. Since the release of the new generation of TopSolid, the performance of the software has grown steadily and has reduced average production times by 30 to 40%.

TopSolid is enriched with a new production solution with the possibility to control robots for machining. Thanks to our collaboration with RoboDK and Stäubli, leader in robotic cell industrialization, Missler Software offers a simple, efficient and economical solution. On the occasion of Industry 2016, visitors will be able to watch live demonstrations of the Stäubli robot piloted by TopSolid on our stand M102 Hall 5.

Discover at the same time the highlights of TopSolid'Cam 7.10:

Master deep hole drilling through advanced intersection management

In order to make the most of the new deep drilling tools, which are extremely efficient but very fragile, TopSolid is enriched with advanced management of drilling intersections. The cumulated management of picking / deburring makes it possible to control this process optimally.

Realize your multi-axis holes in a single operation

The analysis of 5-axis holes without creation of posting, having access to all cycles, contouring or emptying, allows users to program in record times. In a single operation with multi-position geometries, a large number of holes can be easily managed.

Accelerate your production with the VoluMill draft.

Missler Software has chosen to increase the level of integration of VoluMill's machining strategies in order to offer these customers the best in terms of modern trajectory calculation algorithms. In addition to 2D machining, the roughing is now available in TopSolid. Based on a constant desire to obtain a constant volume of chips, the VoluMill trajectories shake up the habits. Consequently, it is possible to use a strong axial grip (for a low radial grip), to substantially increase the feed rates while suppressing the vibrations, while preserving the tool lifetimes and the machine axes.

Simplify and Secure Pilot Point Selection

Whether it is a tool positioned with a tilt on a turret or the management of a tilting head, this new management of the piloted points facilitates and secures the choice of points piloted in a particularly ergonomic and effective way.

Integrate the mirror machining file according to EN9100

The EN 9100 standard (aeronautical and spatial complement of the ISO 9001 standard) requires the creation of a document and a separate follow-up of the original for the machining of the mirror parts. Thanks to this innovation, the user can, with one click, generate these documents, duplicate or not the environments and change the approaches.

The French software publisher Missler Software has just launched its newest version of its CAD / CAM software, TopSolid'Cam 7.10. Since the release of the new generation of TopSolid, the performance of the software has grown steadily and has reduced average production times by 30 to 40%.

TopSolid is enriched with a new production solution with the possibility to control robots for machining. Thanks to our collaboration with RoboDK and Stäubli, leader in robotic cell industrialization, Missler Software offers a simple, efficient and economical solution. On the occasion of Industry 2016, visitors will be able to watch live demonstrations of the Stäubli robot piloted by TopSolid on our stand M102 Hall 5.

Discover at the same time the highlights of TopSolid'Cam 7.10:

Master deep hole drilling through advanced intersection management

In order to make the most of the new deep drilling tools, which are extremely efficient but very fragile, TopSolid is enriched with advanced management of drilling intersections. The cumulated management of picking / deburring makes it possible to control this process optimally.

Realize your multi-axis holes in a single operation

The analysis of 5-axis holes without creation of posting, having access to all cycles, contouring or emptying, allows users to program in record times. In a single operation with multi-position geometries, a large number of holes can be easily managed.

Accelerate your production with the VoluMill draft.

Missler Software has chosen to increase the level of integration of VoluMill's machining strategies in order to offer these customers the best in terms of modern trajectory calculation algorithms. In addition to 2D machining, the roughing is now available in TopSolid. Based on a constant desire to obtain a constant volume of chips, the VoluMill trajectories shake up the habits. Consequently, it is possible to use a strong axial grip (for a low radial grip), to substantially increase the feed rates while suppressing the vibrations, while preserving the tool lifetimes and the machine axes.

Simplify and Secure Pilot Point Selection

Whether it is a tool positioned with a tilt on a turret or the management of a tilting head, this new management of the piloted points facilitates and secures the choice of points piloted in a particularly ergonomic and effective way.

Integrate the mirror machining file according to EN9100

The EN 9100 standard (aeronautical and spatial complement of the ISO 9001 standard) requires the creation of a document and a separate follow-up of the original for the machining of the mirror parts. Thanks to this innovation, the user can, with one click, generate these documents, duplicate or not the environments and change the approaches.