Better tools for better work. This is even more evident and unavoidable in milling bituminous mixes, concrete or both, as well as in soil treatment. Prematurely used tools cause immobilisation of road milling machines, failure to respect the deadlines of the site and exceeding the budget. The new Road King range of milling peaks from Kennametal offers optimized tools, synonymous with better performance.

Road King from Kennametal has a sharper head that facilitates penetration and reduces stress on the collar, retainer and fastening system.

"Many factors contribute to increased wear and tear on tooling systems," says Thomas Chudowski, Senior World Project Manager of the Kennametal Road Rehabilitation Division. Site conditions (road materials, temperature) impose certain choices in terms of depth of cut, machine speed, cooling system, support system and machine power, some of which may be influenced by The operator positively or negatively. "He can choose the type of tool, adjust the speed and depth of cut and of course have an influence on the degree of maintenance of his machine, especially on the cutting unit. "

The type of worksite has so far imposed a choice of tool. An undersized tool for milling will result in too rapid wear, resulting in more downtime to replace the peaks. Conversely, a tool too big for a low power machine will slow it down. The lifetime of the tool may be extended, but the performance of the machine will be insufficient, especially when the asphalt is laid down immediately after milling.

Subcontractors responsible for existing recycling projects generally require a heavier tool body, while in the case of road milling, a finer body improves the performance of the machine. The new Road King range from Kennametal offers a single tooling system that is suitable for both rehabilitation and road milling projects, a significant advantage for subcontractors.

This range benefits from a wide range of optimized features, including:

- The design of the tool head facilitates penetration and reduces pressure on the washer, retainer and fastening system.

- A wide range of optimized carbide insert types (flat base and valve seat base) are available for different working conditions, while a unique head type is compatible with these inserts, greatly simplifying management Of peak stocks.

- The increased hardness of the heads of all these peaks increases their resistance to wear.

- The grooves promote much more rotation of the peak, which slows down the wear of the insert and the head of the tool.

- The design of the head also removes the costats of the tool, which reduces the accumulation of fines between door peak and the tail of the peak.

- The wider ring optimizes the protection of the tool holder.

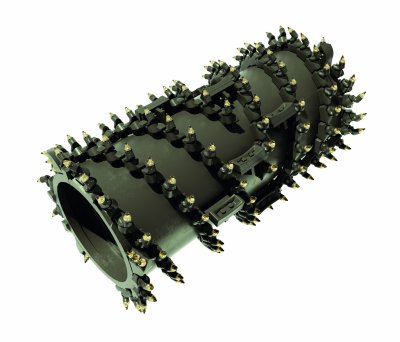

Increased expertise in drum design and support systems

In addition, Kennametal provides unrivaled support, with decades of experience in the design and manufacture of tool drum systems, including milling drums, as well as a full range of conical tools, sleeves And blocks in various configurations, including solder blocks and patented quick change systems requiring no welding and, in some applications, no bolts.

In addition to the latest tools, Kennametal highlights the importance of tailor-made drum design offices as they can play an essential role in helping users achieve the expected productivity. Kennametal's engineers can adapt the design of the drums to the parameters specified by the customer, taking into account user-selectable profile elements: positioning plan, diameter, width, Speed ??of travel and number of revolutions per minute. They then determine the total number of peaks required, the total cutting width, the contact angle per side, the radial distance, the coverage angle and the ejector clearance estimate. Drum configurations for different road conditions and specifications of road machine manufacturers are also available.

"Performance is at the heart of the new Road King range, and tests have demonstrated notable improvements related to this new concept. In a challenging economic environment, Road King is a tool that will reduce supplier costs while providing improved milling performance, "adds Chudowski.

Road King from Kennametal has a sharper head that facilitates penetration and reduces stress on the collar, retainer and fastening system.

"Many factors contribute to increased wear and tear on tooling systems," says Thomas Chudowski, Senior World Project Manager of the Kennametal Road Rehabilitation Division. Site conditions (road materials, temperature) impose certain choices in terms of depth of cut, machine speed, cooling system, support system and machine power, some of which may be influenced by The operator positively or negatively. "He can choose the type of tool, adjust the speed and depth of cut and of course have an influence on the degree of maintenance of his machine, especially on the cutting unit. "

The type of worksite has so far imposed a choice of tool. An undersized tool for milling will result in too rapid wear, resulting in more downtime to replace the peaks. Conversely, a tool too big for a low power machine will slow it down. The lifetime of the tool may be extended, but the performance of the machine will be insufficient, especially when the asphalt is laid down immediately after milling.

Subcontractors responsible for existing recycling projects generally require a heavier tool body, while in the case of road milling, a finer body improves the performance of the machine. The new Road King range from Kennametal offers a single tooling system that is suitable for both rehabilitation and road milling projects, a significant advantage for subcontractors.

This range benefits from a wide range of optimized features, including:

- The design of the tool head facilitates penetration and reduces pressure on the washer, retainer and fastening system.

- A wide range of optimized carbide insert types (flat base and valve seat base) are available for different working conditions, while a unique head type is compatible with these inserts, greatly simplifying management Of peak stocks.

- The increased hardness of the heads of all these peaks increases their resistance to wear.

- The grooves promote much more rotation of the peak, which slows down the wear of the insert and the head of the tool.

- The design of the head also removes the costats of the tool, which reduces the accumulation of fines between door peak and the tail of the peak.

- The wider ring optimizes the protection of the tool holder.

Increased expertise in drum design and support systems

In addition, Kennametal provides unrivaled support, with decades of experience in the design and manufacture of tool drum systems, including milling drums, as well as a full range of conical tools, sleeves And blocks in various configurations, including solder blocks and patented quick change systems requiring no welding and, in some applications, no bolts.

In addition to the latest tools, Kennametal highlights the importance of tailor-made drum design offices as they can play an essential role in helping users achieve the expected productivity. Kennametal's engineers can adapt the design of the drums to the parameters specified by the customer, taking into account user-selectable profile elements: positioning plan, diameter, width, Speed ??of travel and number of revolutions per minute. They then determine the total number of peaks required, the total cutting width, the contact angle per side, the radial distance, the coverage angle and the ejector clearance estimate. Drum configurations for different road conditions and specifications of road machine manufacturers are also available.

"Performance is at the heart of the new Road King range, and tests have demonstrated notable improvements related to this new concept. In a challenging economic environment, Road King is a tool that will reduce supplier costs while providing improved milling performance, "adds Chudowski.