New technological innovations for its NCSIMUL CAM module and the first industrial returns

SPRING Technologies, software editor for optimum use of CNC machines, announces the release of the new version NCSIMUL SOLUTIONS, the 10.1, with, among others, and just 6 months after its launch, developments of its module NCSIMUL CAM, the complement of existing FAO.

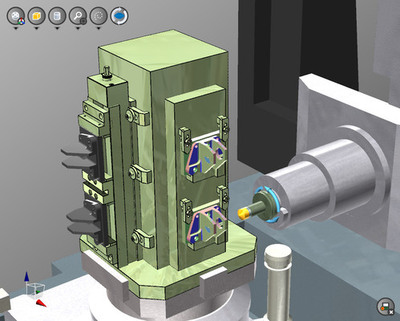

NCSIMUL SOLUTIONS, the unified platform of SPRING Technologies, integrates the modules: NCSIMUL MACHINE, NCSIMUL TOOL, NCSIMUL DNC / MONITOR and NCSIMUL CAM, which was announced in June 2015. It is a complete digital chain for programming control machines Which offers users the possibility to program, check and optimize all types of machines.

The main innovations of NCSIMUL SOLUTIONS 10.1:

NCSIMUL CAM: Optimization of tool changes for multi-part machining (MPM);

NCSIMUL CAM: Function of the rapid modifications / adaptations of the trajectories, conforming to each numerical control machine;

Dynamic interactivity of tool management between the NCSIMUL CAM and NCSIMUL TOOL modules;

NCSIMUL CAM: Improved user interface ergonomics.

The detail

NCSIMUL CAM automates, with the new version, the programming and the launching of the machining of several parts simultaneously, on the same machine, while optimizing the changes of tools. This allows intelligent rearrangement of all multi-part machining sequences (MPM), in order to minimize tool changes automatically. In fact, this evolution improves by about 10% the rate of production of the machines while reducing the time and cost of programming, or manufacturing, of different unit parts or series.

NCSIMUL CAM has a function for editing trajectories imported from a third-party FAO, an ISO program, or direct programming from the module, enabling all modifications to be capitalized.

Indeed, the user manages the editing of cutting parameters and machine options, changes of tool orientation, additions or deletions of points. All these modifications are "historised" and fixed, regardless of the CN machine used. The programmer can then change state to a single "click". Real agility for tracking changes, and saving time for the industrialist.

The new version offers dynamic interactivity between the two modules of the NCSIMUL SOLUTIONS platform: NCSIMUL CAM and NCSIMUL TOOL. The user will be able to update the data of the tool magazine quickly, in order to optimize the management of his tool library available for the generated runs. Moreover, this evolution makes it possible to select the tool of the database by a simple identifier. During the production launch in the workshop, the user can thus verify, easily and immediately, the compatibility of the tools and tool holders for the new machine, validate the project or possibly visualize the elements to be corrected.

Back on the first successes of NCSIMUL CAM:

Since its global availability in October 2015, the NCSIMUL CAM module, the latest addition to the NCSIMUL SOLUTIONS range, has attracted some forty companies, not least: AIRBUS with its subsidiary STELIA, SAFRAN with SNECMA, DASSAULT AVIATION, but also SMEs like FREYSSINET, HALGAND in the aeronautics and UF1 in the automobile industry. The first study and production projects started as early as last December.

Its first feedbacks are unanimous: the concept is unique and the module NCSIMUL CAM simple, intuitive and fast to use. Whereas until now all programming systems have become more complex to take account of the evolutions of numerically controlled machines, trajectories and cutting tools which are increasingly efficient but which are difficult to develop, NCSIMUL CAM simplifies the digital chain and reduces The industrialization times, especially when the arrival of new production machine.

Indeed, in addition to the existing FAO, NCSIMUL CAM 10.1 offers, as standard, the generation of toolpaths in ISO code - verified and optimized - instead of externally developed post-processors developed at a lower cost. In this way, the user can quickly be autonomous in setting up the software package.

NCSIMUL CAM also complements the CAM with the taking into account and optimization of all the complex trajectories of links between the different toolpaths specific to each CNC machine. This NCSIMUL SOLUTIONS module provides a unique flexibility to switch machines in just a few clicks. Today with NCSIMUL CAM it is possible, even for very different kinematics: Milling to Mill-Turn, or 5-axis Head-Head to Plateau - Plateau, regardless of NC controllers (SIEMENS, HEIDENHAIN, FANUC, NUM).

NCSIMUL CAM is the only software to offer this technological and industrial advance.

SPRING Technologies, software editor for optimum use of CNC machines, announces the release of the new version NCSIMUL SOLUTIONS, the 10.1, with, among others, and just 6 months after its launch, developments of its module NCSIMUL CAM, the complement of existing FAO.

NCSIMUL SOLUTIONS, the unified platform of SPRING Technologies, integrates the modules: NCSIMUL MACHINE, NCSIMUL TOOL, NCSIMUL DNC / MONITOR and NCSIMUL CAM, which was announced in June 2015. It is a complete digital chain for programming control machines Which offers users the possibility to program, check and optimize all types of machines.

The main innovations of NCSIMUL SOLUTIONS 10.1:

NCSIMUL CAM: Optimization of tool changes for multi-part machining (MPM);

NCSIMUL CAM: Function of the rapid modifications / adaptations of the trajectories, conforming to each numerical control machine;

Dynamic interactivity of tool management between the NCSIMUL CAM and NCSIMUL TOOL modules;

NCSIMUL CAM: Improved user interface ergonomics.

The detail

NCSIMUL CAM automates, with the new version, the programming and the launching of the machining of several parts simultaneously, on the same machine, while optimizing the changes of tools. This allows intelligent rearrangement of all multi-part machining sequences (MPM), in order to minimize tool changes automatically. In fact, this evolution improves by about 10% the rate of production of the machines while reducing the time and cost of programming, or manufacturing, of different unit parts or series.

NCSIMUL CAM has a function for editing trajectories imported from a third-party FAO, an ISO program, or direct programming from the module, enabling all modifications to be capitalized.

Indeed, the user manages the editing of cutting parameters and machine options, changes of tool orientation, additions or deletions of points. All these modifications are "historised" and fixed, regardless of the CN machine used. The programmer can then change state to a single "click". Real agility for tracking changes, and saving time for the industrialist.

The new version offers dynamic interactivity between the two modules of the NCSIMUL SOLUTIONS platform: NCSIMUL CAM and NCSIMUL TOOL. The user will be able to update the data of the tool magazine quickly, in order to optimize the management of his tool library available for the generated runs. Moreover, this evolution makes it possible to select the tool of the database by a simple identifier. During the production launch in the workshop, the user can thus verify, easily and immediately, the compatibility of the tools and tool holders for the new machine, validate the project or possibly visualize the elements to be corrected.

Back on the first successes of NCSIMUL CAM:

Since its global availability in October 2015, the NCSIMUL CAM module, the latest addition to the NCSIMUL SOLUTIONS range, has attracted some forty companies, not least: AIRBUS with its subsidiary STELIA, SAFRAN with SNECMA, DASSAULT AVIATION, but also SMEs like FREYSSINET, HALGAND in the aeronautics and UF1 in the automobile industry. The first study and production projects started as early as last December.

Its first feedbacks are unanimous: the concept is unique and the module NCSIMUL CAM simple, intuitive and fast to use. Whereas until now all programming systems have become more complex to take account of the evolutions of numerically controlled machines, trajectories and cutting tools which are increasingly efficient but which are difficult to develop, NCSIMUL CAM simplifies the digital chain and reduces The industrialization times, especially when the arrival of new production machine.

Indeed, in addition to the existing FAO, NCSIMUL CAM 10.1 offers, as standard, the generation of toolpaths in ISO code - verified and optimized - instead of externally developed post-processors developed at a lower cost. In this way, the user can quickly be autonomous in setting up the software package.

NCSIMUL CAM also complements the CAM with the taking into account and optimization of all the complex trajectories of links between the different toolpaths specific to each CNC machine. This NCSIMUL SOLUTIONS module provides a unique flexibility to switch machines in just a few clicks. Today with NCSIMUL CAM it is possible, even for very different kinematics: Milling to Mill-Turn, or 5-axis Head-Head to Plateau - Plateau, regardless of NC controllers (SIEMENS, HEIDENHAIN, FANUC, NUM).

NCSIMUL CAM is the only software to offer this technological and industrial advance.