At the Offshore Technology Conference 2016, SKF will present a range of innovations to improve reliability and efficiency in the oil and gas industry. The products and applications presented have been specifically designed to meet the needs of manufacturers and operators looking for more efficient products with a lower total cost of ownership.

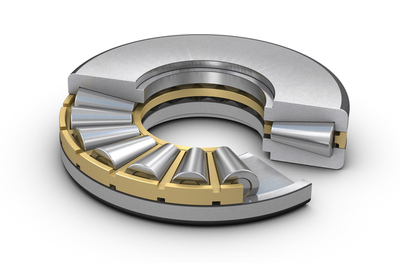

To increase the reliability and service life of mechanical transmissions, SKF has an improved conical roller bearing. Designed with extreme conditions of use at sea, these stops can withstand axial load, shock and high shaft bending. Thanks to pure and highly alloyed steels, optimized geometry and precise SKF manufacturing tolerances, the stops are less friction when they are in operation, their service life is extended and their load capacity is higher. Using proprietary simulation tools, SKF engineers can also offer a customized version of the improved cone roller bearing. Indeed, it has been designed to meet customer requirements and special operating conditions with dimensions, coating and non-standard surface treatment. Additional features for ease of assembly and maintenance can also be provided.

Kaydon steering bearings are used in mechanical transmissions, as well as in a wide range of other offshore applications, from cranes to riser connections. SKF will feature the MTE-324T bearing design, with a 4-point contact design to support radial, axial and torque loads and seals to prevent contamination and increase service life.

Visitors can see the new SKF sensor bearing, an integral solution for operators who want to reduce interruptions by improving monitoring and control of electric motors under extreme conditions. The system combines a reinforced speed sensor with a unique set for easy installation for modern mechanical transmissions and winches. The system, which contains a cylindrical roller bearing or a rigid hybrid ball bearing, a magnetic pulse ring and a sensor incorporated in the sealing cover, is lubricated for life and equipped with seals. The integrated backup sensor option increases reliability, even in the harshest oil and gas environments.

Visitors will also have the opportunity to discuss with SKF experts about customized waterproofing solutions for valve and well control applications. SKF's customized seam offerings include a range of proprietary models and materials. Patented SKF seals, for example, use an anti-extrusion ring that locks mechanically to facilitate and secure the installation, to withstand higher pressures and temperatures and to reduce damage to metal components. SKF is helping customers in the oil and gas industry benefit from efficient sealing solutions through its experience in application engineering and its in-house testing infrastructure that validate their design after testing in The requirements for offshore applications, ie at extremely high temperatures and pressures.

The SKF Multilog IMx-M online system, an advanced solution for monitoring the status of critical offshore equipment, will also be presented. With the SKF @ptitude Monitoring Suite software, the SKF Multilog IMx-M allows end users to protect and improve the reliability of their equipment and avoid machine downtime by offering a complete system for initiating shutdown Machinery, early detection of faults and diagnosis.

The 2016 Offshore Technology Conference is the largest exhibition of equipment for the oil and gas industry. It takes place at the NRG Park convention and exhibition center in Houston, Texas, from May 2 to 5, 2016. Visitors to the event will find SKF at booth 2601.

To increase the reliability and service life of mechanical transmissions, SKF has an improved conical roller bearing. Designed with extreme conditions of use at sea, these stops can withstand axial load, shock and high shaft bending. Thanks to pure and highly alloyed steels, optimized geometry and precise SKF manufacturing tolerances, the stops are less friction when they are in operation, their service life is extended and their load capacity is higher. Using proprietary simulation tools, SKF engineers can also offer a customized version of the improved cone roller bearing. Indeed, it has been designed to meet customer requirements and special operating conditions with dimensions, coating and non-standard surface treatment. Additional features for ease of assembly and maintenance can also be provided.

Kaydon steering bearings are used in mechanical transmissions, as well as in a wide range of other offshore applications, from cranes to riser connections. SKF will feature the MTE-324T bearing design, with a 4-point contact design to support radial, axial and torque loads and seals to prevent contamination and increase service life.

Visitors can see the new SKF sensor bearing, an integral solution for operators who want to reduce interruptions by improving monitoring and control of electric motors under extreme conditions. The system combines a reinforced speed sensor with a unique set for easy installation for modern mechanical transmissions and winches. The system, which contains a cylindrical roller bearing or a rigid hybrid ball bearing, a magnetic pulse ring and a sensor incorporated in the sealing cover, is lubricated for life and equipped with seals. The integrated backup sensor option increases reliability, even in the harshest oil and gas environments.

Visitors will also have the opportunity to discuss with SKF experts about customized waterproofing solutions for valve and well control applications. SKF's customized seam offerings include a range of proprietary models and materials. Patented SKF seals, for example, use an anti-extrusion ring that locks mechanically to facilitate and secure the installation, to withstand higher pressures and temperatures and to reduce damage to metal components. SKF is helping customers in the oil and gas industry benefit from efficient sealing solutions through its experience in application engineering and its in-house testing infrastructure that validate their design after testing in The requirements for offshore applications, ie at extremely high temperatures and pressures.

The SKF Multilog IMx-M online system, an advanced solution for monitoring the status of critical offshore equipment, will also be presented. With the SKF @ptitude Monitoring Suite software, the SKF Multilog IMx-M allows end users to protect and improve the reliability of their equipment and avoid machine downtime by offering a complete system for initiating shutdown Machinery, early detection of faults and diagnosis.

The 2016 Offshore Technology Conference is the largest exhibition of equipment for the oil and gas industry. It takes place at the NRG Park convention and exhibition center in Houston, Texas, from May 2 to 5, 2016. Visitors to the event will find SKF at booth 2601.