Universal Robots launches UR3, the world's most versatile and lightweight table-top robot designed to work with human beings

The Danish pioneer of collaborative robots has created a new, smaller model for light assembly tasks and automated workshops. The UR3 will be launched in Europe on April 13th at the Hannover Messe 2015 in Germany.

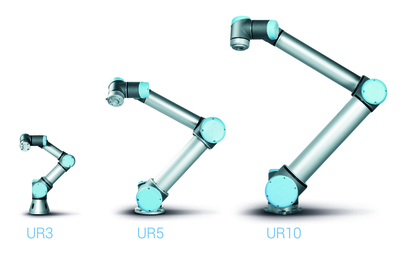

Paris, France, March 17, 2015 - Industrialists from around the world have welcomed the collaborative advantages of the UR5 and UR10 ergonomic robots, which offer remarkable performance at an affordable price and can work alongside the man without a railing. With the new UR3 model, Universal Robots literally puts this market-leading concept on the table.

This new compact table-top robot, weighing just 11 kg, is characterized by a payload of 3 kg as well as a rotation of ± 360 degrees on its joints and infinite on the extreme. These specificities make the UR3 the most versatile and lightweight collaborative table-top robot available today.

Esben Oestergaard, CTO (Technical Director) and co-founder of Universal Robots, led the three-year development phase of the latest robot family UR:

"With the UR3," table-top "robotics become easy, safe and versatile: with its help, a single operator can now complete a task that has hitherto mobilized two people. This is an ideal choice for applications that require six degrees of freedom and where size, safety and cost are of crucial importance. "

"The UR3 is an optimal assistant for assembling, polishing, gluing and screwing tasks that require uniform product quality. Our new robot can also be used as part of a separate, table-mounted workstation to pick, assemble and place parts in optimized workflows. Thanks to its compact size and ease of programming, it passes easily from one task to another to meet changing manufacturing needs, reducing its total cost of ownership (TCO) and the time it takes to return investment. "

The applications of the UR3 range from the manufacture of medical equipment to the manufacture of electronic circuits and components.

"Demand will be largely driven by the automation of production in confined environments. With the UR3, we can now house a robot with six degrees of freedom on a larger number of assembly and manufacturing lines where the installation of large protective cages would not be feasible. The UR3 is ideally suited for operators working in the presence of toxic or hazardous materials, which will also favor the adoption of this new model, "adds Oestergaard.

The UR3 has 15 adjustable advanced safety parameters. These include in particular a force sensor which makes it possible to limit the contact force of the UR3 in the event of an impact with an operator. This force is 150 newtons by default but the robot can be set to stop if it encounters a force of only 50 newtons.

Combining ease of programming with infinite rotation capacity and optimized effort control, the UR3 has everything to assert itself as an expert operator. The robot can grasp screws, set them up and tighten them by applying the right torque. In the field of bonding, the UR3 is capable of dosing exactly the same amount of glue with a constant and uniform pressure along a precisely defined path.

? The UR3 offers the same repeatability, within ± 0.1 mm, as its UR5 and UR10 elders. It can follow the contour of a surface - for example the aluminum edge of a smartphone - by "touch" rather than by precise programming of movements and coordinates, which should take into account more than a hundred data in The application.

"With the UR5 and UR10 models, we see users integrating our robotic arms into applications and industries that we had not imagined at the outset. I am sure that we will be equally astonished to witness the adaptation of the UR3 to new scenarios where the robots had not ventured so far, "Esben Oestergaard expects.

The Danish pioneer of collaborative robots has created a new, smaller model for light assembly tasks and automated workshops. The UR3 will be launched in Europe on April 13th at the Hannover Messe 2015 in Germany.

Paris, France, March 17, 2015 - Industrialists from around the world have welcomed the collaborative advantages of the UR5 and UR10 ergonomic robots, which offer remarkable performance at an affordable price and can work alongside the man without a railing. With the new UR3 model, Universal Robots literally puts this market-leading concept on the table.

This new compact table-top robot, weighing just 11 kg, is characterized by a payload of 3 kg as well as a rotation of ± 360 degrees on its joints and infinite on the extreme. These specificities make the UR3 the most versatile and lightweight collaborative table-top robot available today.

Esben Oestergaard, CTO (Technical Director) and co-founder of Universal Robots, led the three-year development phase of the latest robot family UR:

"With the UR3," table-top "robotics become easy, safe and versatile: with its help, a single operator can now complete a task that has hitherto mobilized two people. This is an ideal choice for applications that require six degrees of freedom and where size, safety and cost are of crucial importance. "

"The UR3 is an optimal assistant for assembling, polishing, gluing and screwing tasks that require uniform product quality. Our new robot can also be used as part of a separate, table-mounted workstation to pick, assemble and place parts in optimized workflows. Thanks to its compact size and ease of programming, it passes easily from one task to another to meet changing manufacturing needs, reducing its total cost of ownership (TCO) and the time it takes to return investment. "

The applications of the UR3 range from the manufacture of medical equipment to the manufacture of electronic circuits and components.

"Demand will be largely driven by the automation of production in confined environments. With the UR3, we can now house a robot with six degrees of freedom on a larger number of assembly and manufacturing lines where the installation of large protective cages would not be feasible. The UR3 is ideally suited for operators working in the presence of toxic or hazardous materials, which will also favor the adoption of this new model, "adds Oestergaard.

The UR3 has 15 adjustable advanced safety parameters. These include in particular a force sensor which makes it possible to limit the contact force of the UR3 in the event of an impact with an operator. This force is 150 newtons by default but the robot can be set to stop if it encounters a force of only 50 newtons.

Combining ease of programming with infinite rotation capacity and optimized effort control, the UR3 has everything to assert itself as an expert operator. The robot can grasp screws, set them up and tighten them by applying the right torque. In the field of bonding, the UR3 is capable of dosing exactly the same amount of glue with a constant and uniform pressure along a precisely defined path.

? The UR3 offers the same repeatability, within ± 0.1 mm, as its UR5 and UR10 elders. It can follow the contour of a surface - for example the aluminum edge of a smartphone - by "touch" rather than by precise programming of movements and coordinates, which should take into account more than a hundred data in The application.

"With the UR5 and UR10 models, we see users integrating our robotic arms into applications and industries that we had not imagined at the outset. I am sure that we will be equally astonished to witness the adaptation of the UR3 to new scenarios where the robots had not ventured so far, "Esben Oestergaard expects.