The new versions of the latest version of VISI, published by Vero Software, are presented at MICRONORA 2014 in Besançon, from 23 to 26 September 2014.

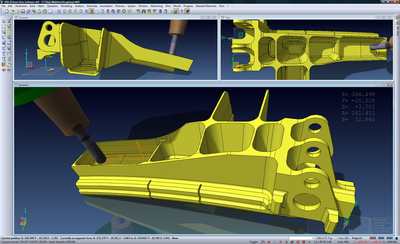

VISI 21, which is scheduled for release at the end of October, contains new 2, 2.5 and 3-axis strategies. A new route simulation is used to manage the ISO output file, giving users a better virtual representation of the part before sending it to the machine. The new version also incorporates new "hybrid" machining strategies that will adapt to different types of finishing paths to respect the geometric shape of the component.

Visitors to MICRONORA were able to see improvements in the management of large volumes of CAD data. These include tools dedicated to the creation and management of multiple cavities, allowing faster and more efficient modification of the components. Users will benefit from improved options and tools for creating geometries, as well as improvements in plastic flow and tooling analysis options.

The new features include changes in wire cutting and milling techniques as well as higher levels of automation. "The user interface has been extensively reviewed to improve the methods and availability of options. The use of dialog boxes and variables is even simpler thanks to the many automated functions. "

VISI Webinar: In the near future, VISI technical teams will be hosting webinars on the latest developments in the various modules (VISI Machining, VISI Progress, VISI Peps Wire and VISI Flow).

VISI 21, which is scheduled for release at the end of October, contains new 2, 2.5 and 3-axis strategies. A new route simulation is used to manage the ISO output file, giving users a better virtual representation of the part before sending it to the machine. The new version also incorporates new "hybrid" machining strategies that will adapt to different types of finishing paths to respect the geometric shape of the component.

Visitors to MICRONORA were able to see improvements in the management of large volumes of CAD data. These include tools dedicated to the creation and management of multiple cavities, allowing faster and more efficient modification of the components. Users will benefit from improved options and tools for creating geometries, as well as improvements in plastic flow and tooling analysis options.

The new features include changes in wire cutting and milling techniques as well as higher levels of automation. "The user interface has been extensively reviewed to improve the methods and availability of options. The use of dialog boxes and variables is even simpler thanks to the many automated functions. "

VISI Webinar: In the near future, VISI technical teams will be hosting webinars on the latest developments in the various modules (VISI Machining, VISI Progress, VISI Peps Wire and VISI Flow).