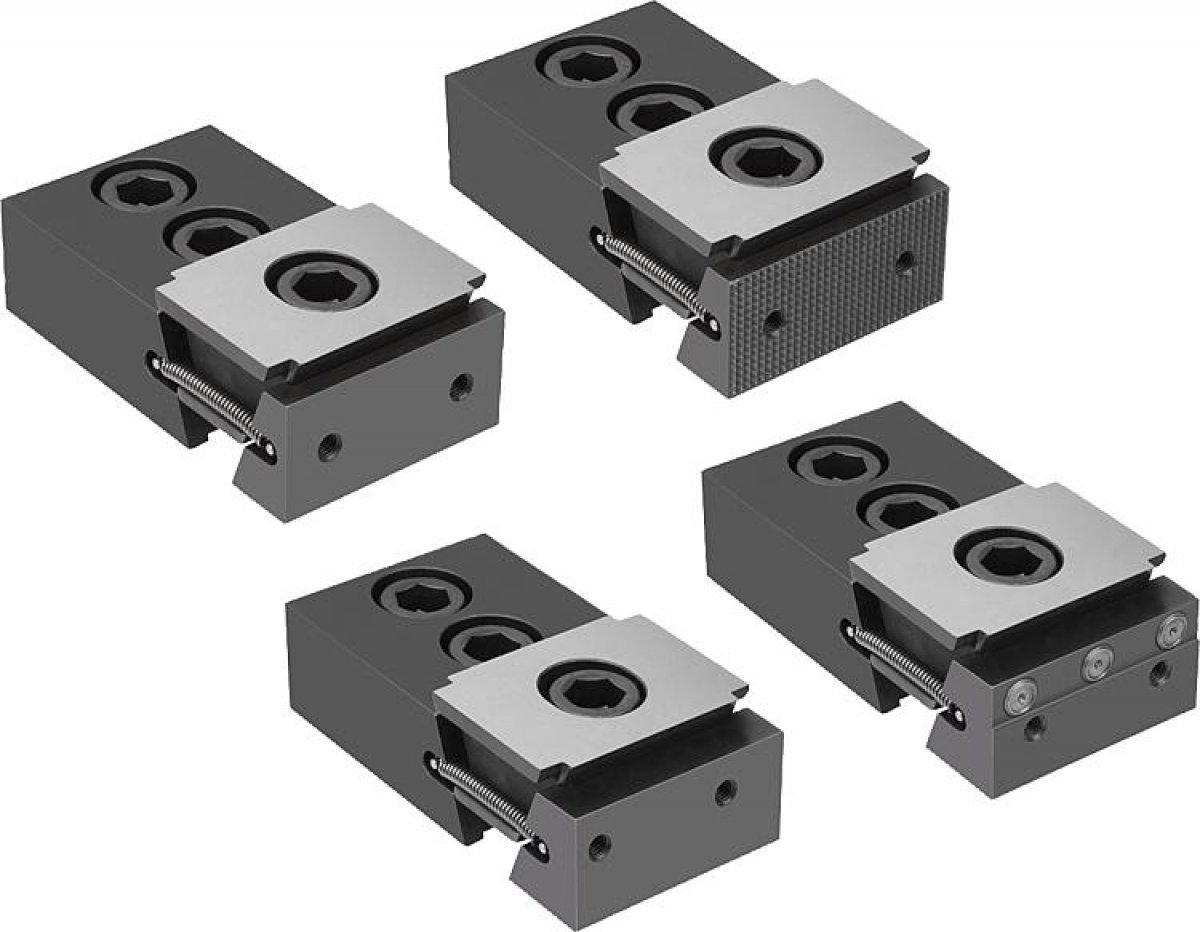

The functioning principle make the wedge clamps ideal for multi-clamping.

The wedge shape creates high clamping forces.

These wedge clamps set into a T-slot for clamping.

Tightening the clamping screw moves the clamping segments outwards and presses the workpiece against the fixed jaws of the machining fixture.

The wedge has a slightly elongated hole allowing for movement to compensate for tolerances.

Displacement: M12 = ±1,0 mm.

Material:

Wedge and jaw segments carbon steel.

Version:

Double wedge and clamping segments hardened, black oxidised.

Note:

The two screw-on holes in the clamping faces also enable seating ledges to be mounted so as to optimise the clamping depth of the workpieces.

The underside is carbide-coated. This increases the coefficient of friction.

Supplied with

Wedge clamps

Fastening screws.

Drawing reference:

Form A: Smooth jaw face

Form B: Serrated jaw face

Form D: With machining allowance

Form E: With jaw pins