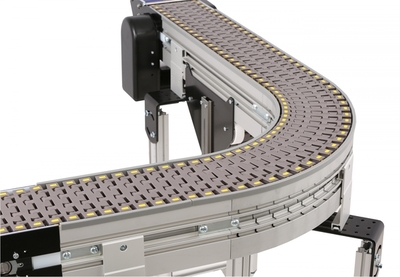

Dorner Launches the Next Generation 3200 Series Platform, Expanding Capabilities for Customers and Providing Increased Flexibility for More Markets including Industry, Packaging and Assembly.

The new line, which debuts this month, is the result of the merger and optimization of the 5200 and 5300 series Dorner conveyors and the 3200 series conveyor platform. The new 3200 series includes flat, Modular and precision. The 3200 Modular Conveyor is part of the first launch phase.

"By merging these two product lines, we have created a platform that combines flexibility and functionality," said Stacy Pabst, marketing director of Dorner Mfg. Corp. "Not only does it offer higher speeds and load capacities, it also makes complex configurations possible with many curves. "

The 3200 series modular conveyor includes many of the features of other Dorner industrial platforms, while benefiting from new features that improve its efficiency and performance.

Among the features of the new 3200 series modular conveyor, a flat end on the side that facilitates the junction with the machine, a maximum capacity of four curve modules, an improved curved conveyor capacity of 200%, curve belt speed 400 feet per minute, a 50% straight detour rail drive size (adapted to the height of the chassis), and a belt weighing module on the curves that reduces the need for maintenance.

Based in Hartland, Wisconsin, USA, Dorner Manufacturing is a world leader in the design, manufacture and distribution of high-quality conveyors and related equipment. Since 1973, companies around the world have been using Dorner conveyors to improve their efficiency and productivity.

The new line, which debuts this month, is the result of the merger and optimization of the 5200 and 5300 series Dorner conveyors and the 3200 series conveyor platform. The new 3200 series includes flat, Modular and precision. The 3200 Modular Conveyor is part of the first launch phase.

"By merging these two product lines, we have created a platform that combines flexibility and functionality," said Stacy Pabst, marketing director of Dorner Mfg. Corp. "Not only does it offer higher speeds and load capacities, it also makes complex configurations possible with many curves. "

The 3200 series modular conveyor includes many of the features of other Dorner industrial platforms, while benefiting from new features that improve its efficiency and performance.

Among the features of the new 3200 series modular conveyor, a flat end on the side that facilitates the junction with the machine, a maximum capacity of four curve modules, an improved curved conveyor capacity of 200%, curve belt speed 400 feet per minute, a 50% straight detour rail drive size (adapted to the height of the chassis), and a belt weighing module on the curves that reduces the need for maintenance.

Based in Hartland, Wisconsin, USA, Dorner Manufacturing is a world leader in the design, manufacture and distribution of high-quality conveyors and related equipment. Since 1973, companies around the world have been using Dorner conveyors to improve their efficiency and productivity.