How can more than one thousand detectors be integrated into an electronic kanban system? Identytec GmbH & Co. KG, based near Hanover, found a solution as innovative as it was logical: remove cables and use wireless position switches.

In 1947, Taiichi Ohno, engineer at Toyota, set up a system of cards card, called kanban. Positioned on the containers of the warehouse, the production staff had to remove the sheets as soon as a container was empty, then place the cards in a dedicated box. In this way, planners were provided with relevant information about the items to be ordered or produced, enabling them to reduce inventory to a minimum without ever breaking down.

E-kanban: Component supply at the touch of a button via ERP

Today, the information flow no longer requires cards, the empty container alerts being done by computer. This type of electronic replenishment according to the "pull" principle is called e-kanban.

Identytec GmbH & Co. KG has developed intelligent hardware and software solutions to meet this specific task. One of the components used is the Tag ID, a mobile call button that allows production technicians to call goods or parts. At the push of a button, the ERP system knows that it must replenish the assembly station concerned.

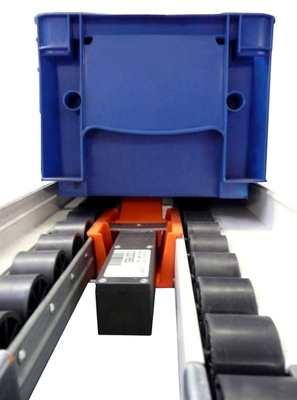

With Identytec's Shell ID, the reconstruction of a shelving is done automatically, without even having to press a button. In this system, a drawer conveyor is equipped with a position switch. By means of the rocker lever, the switch detects whether the rack is full or empty. As soon as a production or assembly technician removes a container, the position switch automatically sends information to a Wi-Fi communication unit, which in turn triggers a command in the ERP system.

Transmission of signals for more than 1,000 transmitters

ID Connector, the software developed by Identytec for this e-kanban system, creates a link between equipment such as conveyors to control stations and also to the ERP system. Other equipment, such as labelers or mobile terminals on forklift trucks, can be integrated in the same way in the IT structure.

Automotive manufacturers are among the main users of e-kanban management systems, equipping many assembly stations with this efficient method of procurement. This system facilitates the simultaneous management of more than 1,000 items in an assembly line or production site.

Regarding the choice of detectors, Identytec has decided to adopt an innovative technology, allowing to reduce the costs while maintaining the flexibility. The wireless radio position switches RF 96 TK have been chosen as transmitters for the individual detection of conveyors. These switching devices use a very stable and low-energy radio protocol, allowing a radio link to the receiver with extreme reliability and high transmission quality.

When the parts to be detected are rather light or the design of the shelves is so compact that the lever switches are impossible to mount, a wireless opto-electronic detector, RF 96 LT, is used on-site. It operates according to the same radio protocol as electromechanical switches.

High transmission reliability, long battery life

All of the aforementioned switching devices come from the product lines of steute Schaltgeräte GmbH & Co. KG. The energy required to send the signals is generated either by dynamo (transformation of the mechanical movement into electricity or - as in these examples - by long-term batteries. Which allows the batteries to have a lifetime of more than 4 years.

By assigning the transmitters to the receivers, configured in a few steps by self-learning before the first use, many wireless switches can be used in parallel. Previous experiments in various fields of application have demonstrated that the operation of the devices does not interfere with other wireless networks such as Wi-Fi.

In electronic kanban systems, a wireless lever switch detects when a user removes a container and sends a signal corresponding to the ERP system

Battery-operated cordless switch, operating according to electromagnetic principle

For evaluation of radio signals, users can choose between single channel and multichannel receivers installed in the control cabinet. A practical, easy-to-install and innovative solution for hard-to-wire areas that can be adapted by steute to the specific needs of a user.

Identytec's electronic kanban systems are only one of many possible uses of radio switches in workflow management.

Wire drawers and stepping piles are used, for example, to open automatic doors of a warehouse directly from a forklift truck. This device is often installed on the ceiling at a considerable height, which means that the wiring is often more expensive than the device itself. The cord pulls or buttons make it possible to avoid such an additional cost.

Another example of application is the use of cord pullers on production lines. As soon as an operator detects a quality problem, he pulls the cord to stop the entire chain. In doing so, it also sends a signal to the control station, which can then immediately eliminate the cause of the failure in order to prevent quality degradation over the entire chain.

In 1947, Taiichi Ohno, engineer at Toyota, set up a system of cards card, called kanban. Positioned on the containers of the warehouse, the production staff had to remove the sheets as soon as a container was empty, then place the cards in a dedicated box. In this way, planners were provided with relevant information about the items to be ordered or produced, enabling them to reduce inventory to a minimum without ever breaking down.

E-kanban: Component supply at the touch of a button via ERP

Today, the information flow no longer requires cards, the empty container alerts being done by computer. This type of electronic replenishment according to the "pull" principle is called e-kanban.

Identytec GmbH & Co. KG has developed intelligent hardware and software solutions to meet this specific task. One of the components used is the Tag ID, a mobile call button that allows production technicians to call goods or parts. At the push of a button, the ERP system knows that it must replenish the assembly station concerned.

With Identytec's Shell ID, the reconstruction of a shelving is done automatically, without even having to press a button. In this system, a drawer conveyor is equipped with a position switch. By means of the rocker lever, the switch detects whether the rack is full or empty. As soon as a production or assembly technician removes a container, the position switch automatically sends information to a Wi-Fi communication unit, which in turn triggers a command in the ERP system.

Transmission of signals for more than 1,000 transmitters

ID Connector, the software developed by Identytec for this e-kanban system, creates a link between equipment such as conveyors to control stations and also to the ERP system. Other equipment, such as labelers or mobile terminals on forklift trucks, can be integrated in the same way in the IT structure.

Automotive manufacturers are among the main users of e-kanban management systems, equipping many assembly stations with this efficient method of procurement. This system facilitates the simultaneous management of more than 1,000 items in an assembly line or production site.

Regarding the choice of detectors, Identytec has decided to adopt an innovative technology, allowing to reduce the costs while maintaining the flexibility. The wireless radio position switches RF 96 TK have been chosen as transmitters for the individual detection of conveyors. These switching devices use a very stable and low-energy radio protocol, allowing a radio link to the receiver with extreme reliability and high transmission quality.

When the parts to be detected are rather light or the design of the shelves is so compact that the lever switches are impossible to mount, a wireless opto-electronic detector, RF 96 LT, is used on-site. It operates according to the same radio protocol as electromechanical switches.

High transmission reliability, long battery life

All of the aforementioned switching devices come from the product lines of steute Schaltgeräte GmbH & Co. KG. The energy required to send the signals is generated either by dynamo (transformation of the mechanical movement into electricity or - as in these examples - by long-term batteries. Which allows the batteries to have a lifetime of more than 4 years.

By assigning the transmitters to the receivers, configured in a few steps by self-learning before the first use, many wireless switches can be used in parallel. Previous experiments in various fields of application have demonstrated that the operation of the devices does not interfere with other wireless networks such as Wi-Fi.

In electronic kanban systems, a wireless lever switch detects when a user removes a container and sends a signal corresponding to the ERP system

Battery-operated cordless switch, operating according to electromagnetic principle

For evaluation of radio signals, users can choose between single channel and multichannel receivers installed in the control cabinet. A practical, easy-to-install and innovative solution for hard-to-wire areas that can be adapted by steute to the specific needs of a user.

Identytec's electronic kanban systems are only one of many possible uses of radio switches in workflow management.

Wire drawers and stepping piles are used, for example, to open automatic doors of a warehouse directly from a forklift truck. This device is often installed on the ceiling at a considerable height, which means that the wiring is often more expensive than the device itself. The cord pulls or buttons make it possible to avoid such an additional cost.

Another example of application is the use of cord pullers on production lines. As soon as an operator detects a quality problem, he pulls the cord to stop the entire chain. In doing so, it also sends a signal to the control station, which can then immediately eliminate the cause of the failure in order to prevent quality degradation over the entire chain.