Challenge: To increase unmanned tool changing and eliminate chip-handling problems in turning centres.

Solution: Transition to automatic tool changing and higher coolant pressures in turning centres.

Turning centres dominate in the manufacturing industry. Regardless of size, they tend to have unnecessarily long stops for manual tool changing and a coolant system whereby coolants flow passively into the cutting zone. Ongoing development work in these machines is aimed at minimizing both planned and unplanned machine stoppages.

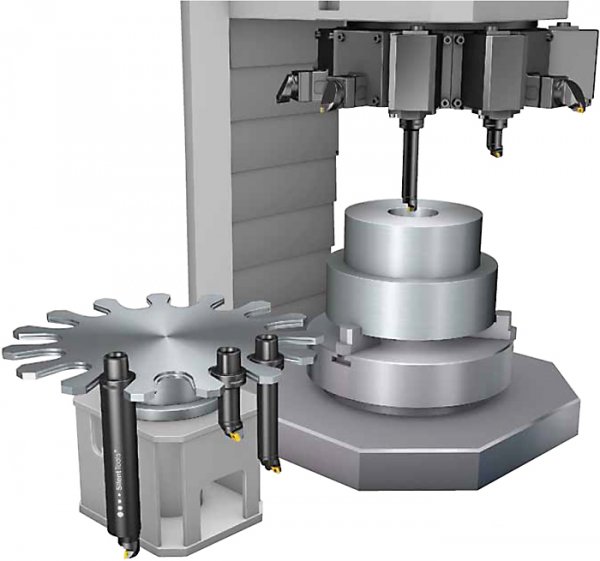

Although nobody today would consider buying a machining centre that did not have automatic tool changing, automatic tool changing is not standard in turning centres. This is due in part to the lack of a common tool-holding interface for turrets that allows for automated tool changing. Process-wise, horizontal turning centres have evolved to include a Y-axis, double turrets, subspindles and monitoring and measuring for efficient high-volume manufacturing, making them extremely efficient and versatile during actual machining. Vertical turning centres are now evolving to the next stage where automatic tool changing is an option. This is driven by the need in the manufacturing industry to make machines more unmanned and versatile, to minimize moving parts and to have the capability of using longer boring bars without limiting turret positions.

It’s clear that automatic tool changing equipment and standard turret interfaces in the future will be part of the machine concept. Tooling developments are driven by machining developments and vice versa, with the manufacturing industry driving or reacting to new technology and with machining costs being the bottom line.

High-pressure coolant systems are part of most modern machines, but the majority of these are not used in a way that makes a real difference to the cutting process. There are concepts such as CoroTurn HP that harness common high-pressure capabilities in the region of 30 to 80 bars. In these, accurate coolant jets with laminar parallel flow are directed to lift the chip being generated, reduce heat and improve chip control in turning centres, thus improving performance and security for unmanned production in most materials.

But to achieve maximum benefit from high-pressure assisted turning in materials with more demanding chip breaking, even higher coolant velocity and pressure ? up to 150 bars ? are required to cover the majority of applications. This will have huge advantages for the cutting process and chip management in the machining zone and on the chip conveyor. The new capability must be a consideration in turning centres where demanding and long-chipping materials are a potential risk for long chip-clearing times and reliability in order to realize unmanned machining.

Solutions are based on the ISO-standardized Coromant Capto modular tool-holding system, which for many years has been widely used as the leading manual quick-change system for turning centres with both static ?? and driven tool holders. Today vertical lathes and multi-task machines use the same interface combined with automatic tool changing capabilities. All indications for the next chapter in the development of Coromant Capto will be in the development of turning centres that incorporate automatic tool changing.

In preparation for an increase of coolant pressure, new clamping mechanisms have been developed with sealing that will withstand at least 150 bar pressure. This is for manual clamping units in turning centres as well as for spindle clamping in rotating spindles on multi-functional machines. A major advantage of the ongoing development is that the interface remains consistent, with existing cutting units and adapters being fully compatible.

Vertical turning centres

Like machining centres, vertical turning centres are evolving to automatic tool changing ? partly because of the need to remove long tools that obstruct machining with shorter tools, and partly because of the need for more efficiency and being part of unmanned production. The development of Coromant Capto will be the common interface for static and driven tools and the norm for establishing automatic tool changes.