The leading supplier of automotive tires and components Continental Automotive has specified Crastin® Super Fast (SF) resins in a series of thermal hoods designed to protect the delicate electronics of engine management, a choice dictated by shorter cycle times and more High fluidity compared to standard PBT.

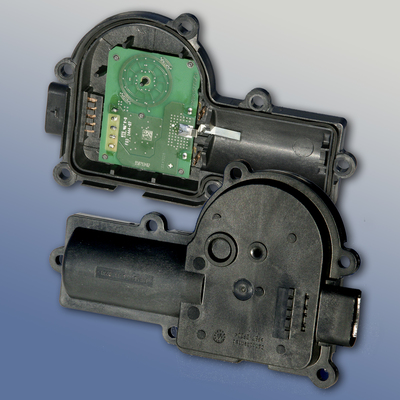

This housing is used for a sensor module for the thermal management of the motor

The PBT Crastin® SF can be applied without any modification to the injection molding presses used for the standard PBT or to a smaller machine thanks to its effectiveness at lower injection pressures, its fluidity being considerably greater - up to 30% - to that of a standard PBT. This exceptional fluidity makes it possible to produce parts that are less thick, lighter and more complex in many electrical and electronic applications such as connection systems, automotive sensors, relays, control units, coils, switches and solenoid valves.

Moreover, the very low moisture absorption of Crastin® compared to the polyamide traditionally used for this type of component considerably reduces the problem of degradation by moisture of encapsulated electrical devices.

"The Crastin® SK615SF PBT polymer is used by Continental as the material of choice for the cost-effective production of thermal hoods because the mold fills more easily and the cycle times are shorter than with the standard GF30 PBT," explains Régis Sarrahy, technical specialist - Injection Molding of Continental Automotive France SAS.

"There is a growing demand for a product that allows molders to benefit from shorter cycle times, increase productivity and reduce production costs," said Antonio Nerone, DuPont Performance Polymers' world leader in Connectors and Electrical Components . "Crastin® SF can significantly increase productivity - up to 30% - and significantly reduce production costs. It can also generate energy savings because this ultra-fast resin can be injected at lower temperatures and pressures than with standard PBT grades. "

Crastin® SF is offered in a non-reinforced grade, and in two others reinforced by 15 or 30% of glass fibers, in black or natural color. Note that black grades can be laser-marked, which permits the permanent marking of a product, brand and specifications, and greatly reduces the risk of counterfeiting.

This housing is used for a sensor module for the thermal management of the motor

The PBT Crastin® SF can be applied without any modification to the injection molding presses used for the standard PBT or to a smaller machine thanks to its effectiveness at lower injection pressures, its fluidity being considerably greater - up to 30% - to that of a standard PBT. This exceptional fluidity makes it possible to produce parts that are less thick, lighter and more complex in many electrical and electronic applications such as connection systems, automotive sensors, relays, control units, coils, switches and solenoid valves.

Moreover, the very low moisture absorption of Crastin® compared to the polyamide traditionally used for this type of component considerably reduces the problem of degradation by moisture of encapsulated electrical devices.

"The Crastin® SK615SF PBT polymer is used by Continental as the material of choice for the cost-effective production of thermal hoods because the mold fills more easily and the cycle times are shorter than with the standard GF30 PBT," explains Régis Sarrahy, technical specialist - Injection Molding of Continental Automotive France SAS.

"There is a growing demand for a product that allows molders to benefit from shorter cycle times, increase productivity and reduce production costs," said Antonio Nerone, DuPont Performance Polymers' world leader in Connectors and Electrical Components . "Crastin® SF can significantly increase productivity - up to 30% - and significantly reduce production costs. It can also generate energy savings because this ultra-fast resin can be injected at lower temperatures and pressures than with standard PBT grades. "

Crastin® SF is offered in a non-reinforced grade, and in two others reinforced by 15 or 30% of glass fibers, in black or natural color. Note that black grades can be laser-marked, which permits the permanent marking of a product, brand and specifications, and greatly reduces the risk of counterfeiting.