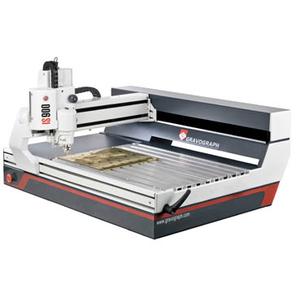

This new mechanical engraving machine is intended for the etching of nameplates or the cutting and engraving of sheets of any material, down to aluminum.

IS 900 can burn up to 100 mm / sec on an extended surface of 660x460 mm, ensuring high productivity for medium and large engravings but also for cutting or milling.

This IS 900 mechanical engraving machine is distinguished by its intelligence, its ergonomics, and its many innovations.

The intelligence of the machine is first provided by the IQ + electronics. Specifically developed by Gravograph for its range of engraving machines, this new electronics has the characteristic of increasing

Working speeds up to 50% and thus reach a maximum speed of 100mm / s. IQ PLUS also offers new functions such as "Point n'Shoot". It also allows the machine to integrate very easily, in "plug and play" mode, all types of driven accessories such as additional spindle drives, chip suction functions, lubrication, etc.

Then, with regard to ergonomics, the innovative design, registered model Gravograph, of the ISO 900, allows it to pass bands of unlimited length, with an engraving field of 660x460 mm. The

Loading can also be done by the open area, from the rear of the machine. It can be placed either in the middle of a workshop or against a wall or at the angle of both walls, and whatever its layout, all the features remain available. IS 900 is also 100% compatible with the Braille Dispenser Kit from Gravograph.

In a very simple way the customer can thus engrave, and deposit the metal balls in the plates to create Braille characters. The fastening of large plates can also be carried out with one hand for greater productivity. All fasteners are locked at once by a single handle. The plates are thus laid and fixed in less than 10 seconds.

Finally, it is its many innovations that distinguish it from other models of the market.

First, the "Terrain Follower" allows the IS 900 machine to perfectly etch even a non-flat surface, following the evolution of the sheet and its height with an optical sensor. Secondly, the

Function "Point n'Shoot" proposes a laser pointer to position the engraving visually on the object and simulate the engraving work before carrying out the task to be carried out.

IS 900 can burn up to 100 mm / sec on an extended surface of 660x460 mm, ensuring high productivity for medium and large engravings but also for cutting or milling.

This IS 900 mechanical engraving machine is distinguished by its intelligence, its ergonomics, and its many innovations.

The intelligence of the machine is first provided by the IQ + electronics. Specifically developed by Gravograph for its range of engraving machines, this new electronics has the characteristic of increasing

Working speeds up to 50% and thus reach a maximum speed of 100mm / s. IQ PLUS also offers new functions such as "Point n'Shoot". It also allows the machine to integrate very easily, in "plug and play" mode, all types of driven accessories such as additional spindle drives, chip suction functions, lubrication, etc.

Then, with regard to ergonomics, the innovative design, registered model Gravograph, of the ISO 900, allows it to pass bands of unlimited length, with an engraving field of 660x460 mm. The

Loading can also be done by the open area, from the rear of the machine. It can be placed either in the middle of a workshop or against a wall or at the angle of both walls, and whatever its layout, all the features remain available. IS 900 is also 100% compatible with the Braille Dispenser Kit from Gravograph.

In a very simple way the customer can thus engrave, and deposit the metal balls in the plates to create Braille characters. The fastening of large plates can also be carried out with one hand for greater productivity. All fasteners are locked at once by a single handle. The plates are thus laid and fixed in less than 10 seconds.

Finally, it is its many innovations that distinguish it from other models of the market.

First, the "Terrain Follower" allows the IS 900 machine to perfectly etch even a non-flat surface, following the evolution of the sheet and its height with an optical sensor. Secondly, the

Function "Point n'Shoot" proposes a laser pointer to position the engraving visually on the object and simulate the engraving work before carrying out the task to be carried out.