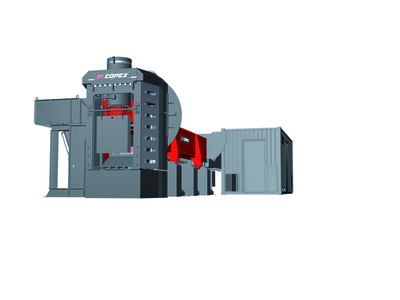

With 70 years of experience in the design and manufacture of hydraulic equipment for the recycling of scrap and metals, COPEX is launching a new range of S-Wing shearing presses.

These new flap shears presses, specially designed for shearing and compacting light to medium heavy scrap, are based on two major advantages: the S-Wing are free of the road constraints of mobile models and have a reinforced structure that guarantees their great robustness. The specific kinematics of the shutters, each equipped with a significant overtravel, also allows them to achieve remarkable compaction performances. Easy to install, they also require a simple and economical civil engineering. Complementary to the Reflex and Lidex ranges, the S-Wing comes in three cutting forces: 650, 900 and 1000 tons.

The new COPEX S-Wing shear presses are devoted to the processing of light to medium-weight scrap. They concentrate all the experience, the robustness and the performance of the Breton industrialist, and have two major assets to conquer the market: high durability Thanks to their reinforced structure, and high compacting performance due to flap performance. Added to this is an on-site installation to limit the investment cost.

Marketed in three models depending on the cutting force (650 t, 900 t and 1000 t), these new flap shear presses are characterized by a large compression box and a particularly powerful shear designed to treat various scrap: profiles and Long tubes, welded structures (cladding, crinolines), scrap collecting and various elements (tanks, tanks, chassis, VHU ...).

S-Wing, a concentration of know-how and experience COPEX:

- Reliability of the extended slide guide: Simultaneous movements of the shear and presser allow the S-Wing range to achieve very high cutting speeds without losing performance despite intensive use. The control of the clearance between the blades makes it possible to reduce the energy consumption while helping to increase the service life of the machine.

- High compaction performances obtained by the high overcurrents of each shutter and the simultaneous movements. The specific kinematics of the shutters promotes an optimal wrapping during the compaction, and makes it possible to reduce the cycle times.

S-Wing can also be supplied with a loading bin to charge the scrap metal in masked time.

- Durability and longevity thanks to a reinforced body (covered with replaceable abrasion-resistant wear plates) and an integral protection of the pusher rod and the cylinder jacks. The great overtravel of each flap reduces the wear of the plates during the advance of the pusher. And all hydraulic connections, electrical wiring and sensitive elements (type magnetostrictive sensors and laser) benefit from a reinforced protection against shocks and scrap.

- Ease of installation of the machine requiring less civil engineering, for faster investment amortization. And thanks to a self-supporting chassis placed under the compression box, which allows an optimal distribution of forces.

- Operational comfort thanks to integrated technological supports. A remote control with a screen allows the operator to quickly visualize all the operating data. A second control screen on the rack allows to anticipate maintenance operations on the press or on the electrical and hydraulic equipment of the soundproof container.

These new flap shears presses, specially designed for shearing and compacting light to medium heavy scrap, are based on two major advantages: the S-Wing are free of the road constraints of mobile models and have a reinforced structure that guarantees their great robustness. The specific kinematics of the shutters, each equipped with a significant overtravel, also allows them to achieve remarkable compaction performances. Easy to install, they also require a simple and economical civil engineering. Complementary to the Reflex and Lidex ranges, the S-Wing comes in three cutting forces: 650, 900 and 1000 tons.

The new COPEX S-Wing shear presses are devoted to the processing of light to medium-weight scrap. They concentrate all the experience, the robustness and the performance of the Breton industrialist, and have two major assets to conquer the market: high durability Thanks to their reinforced structure, and high compacting performance due to flap performance. Added to this is an on-site installation to limit the investment cost.

Marketed in three models depending on the cutting force (650 t, 900 t and 1000 t), these new flap shear presses are characterized by a large compression box and a particularly powerful shear designed to treat various scrap: profiles and Long tubes, welded structures (cladding, crinolines), scrap collecting and various elements (tanks, tanks, chassis, VHU ...).

S-Wing, a concentration of know-how and experience COPEX:

- Reliability of the extended slide guide: Simultaneous movements of the shear and presser allow the S-Wing range to achieve very high cutting speeds without losing performance despite intensive use. The control of the clearance between the blades makes it possible to reduce the energy consumption while helping to increase the service life of the machine.

- High compaction performances obtained by the high overcurrents of each shutter and the simultaneous movements. The specific kinematics of the shutters promotes an optimal wrapping during the compaction, and makes it possible to reduce the cycle times.

S-Wing can also be supplied with a loading bin to charge the scrap metal in masked time.

- Durability and longevity thanks to a reinforced body (covered with replaceable abrasion-resistant wear plates) and an integral protection of the pusher rod and the cylinder jacks. The great overtravel of each flap reduces the wear of the plates during the advance of the pusher. And all hydraulic connections, electrical wiring and sensitive elements (type magnetostrictive sensors and laser) benefit from a reinforced protection against shocks and scrap.

- Ease of installation of the machine requiring less civil engineering, for faster investment amortization. And thanks to a self-supporting chassis placed under the compression box, which allows an optimal distribution of forces.

- Operational comfort thanks to integrated technological supports. A remote control with a screen allows the operator to quickly visualize all the operating data. A second control screen on the rack allows to anticipate maintenance operations on the press or on the electrical and hydraulic equipment of the soundproof container.