The automotive supplier automated a dash control on dashboard skin using a Keyence LJ-G sensor. This results in a stable measurement and a rapid return on investment.

Faurecia is an expert in the design, development, manufacture and delivery of automotive equipment. With 320 sites in 34 countries, including 30 major research and development centers, Faurecia is the world leader in each of its four activities: Automotive seating, Interior Systems (# 1 worldwide) N ° 1 worldwide), Emissions control technologies (n ° 1 worldwide) and Automotive exteriors (n ° 1 in Europe).

Faurecia Interior Systems' research and development center in Méru, Oise, has designed a control center that has been installed in the factory.

A security check

The dashboard skins must have a small notch in order to facilitate the exit of the Airbag in the event of an accident. Proper performance of this notch is essential for passenger safety. A measurement using the principle of laser triangulation is carried out. It consists in reconstituting the profile of the notch according to 800 points. This determines the residual thickness, that is to say the thickness of the skin at the point of the deepest point of the notch.

"We used to do this manually with a microscope. Besides the very long time needed to carry out this inspection, it was necessary to destroy the part. We therefore decided to implement a non-contact measurement solution that could offer repeatability and simplicity of integration, "explains Lionel Marlier, Director of Security & Regulation at Faurecia Interior Systems.

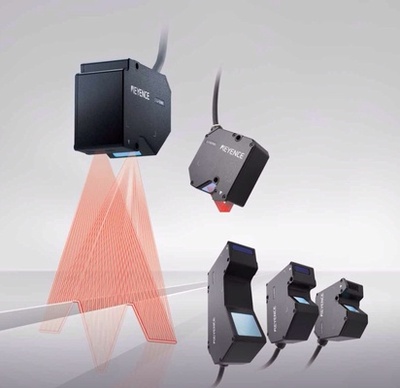

The LJ-G is a 2D laser profilometer capable of performing on-the-fly measurements on production lines. The equipment consists of a controller, a monitor and laser heads, it is distinguished by its simplicity of setting. Its configuration menu allows unsuspecting users to configure the settings without difficulty. The software also facilitates control by a PC. The data is exported to a spreadsheet for analysis.

"The integration was very simple and the measurement remains stable without specific intervention on our part," added Lionel Marlier.

In the case of this control carried out at the factory, the skins may be of different colors: black, white or maroon. The LJ-G is not affected by the color and lighting conditions. This feature comes from the E3-CMOS image sensor, developed for industrial vision. It offers a dynamic range 300 times more extensive than traditional sensors. It can thus perform measurements on all surfaces regardless of color or reflectivity.

In addition, the LJ-G has a position-shifting function that allows stable measurements even when the targets are not properly positioned or tilted.

The LJ-G Series offers a repeatability of 1 micron with a sampling rate of 3.8 ms.

"Effectively, the control is twice as fast. It can be carried out in the production area, which improves our responsiveness, "explains Lionel Marlier.

"The implementation of the Keyence solution is part of a process of continuous quality improvement, but this automated measurement has also proved profitable. The control is no longer destructive, it is faster and requires less human intervention. Overall, we achieved a return on investment in less than a year while improving the accuracy of the measurement, "concludes Lionel Marlier.

Faurecia is an expert in the design, development, manufacture and delivery of automotive equipment. With 320 sites in 34 countries, including 30 major research and development centers, Faurecia is the world leader in each of its four activities: Automotive seating, Interior Systems (# 1 worldwide) N ° 1 worldwide), Emissions control technologies (n ° 1 worldwide) and Automotive exteriors (n ° 1 in Europe).

Faurecia Interior Systems' research and development center in Méru, Oise, has designed a control center that has been installed in the factory.

A security check

The dashboard skins must have a small notch in order to facilitate the exit of the Airbag in the event of an accident. Proper performance of this notch is essential for passenger safety. A measurement using the principle of laser triangulation is carried out. It consists in reconstituting the profile of the notch according to 800 points. This determines the residual thickness, that is to say the thickness of the skin at the point of the deepest point of the notch.

"We used to do this manually with a microscope. Besides the very long time needed to carry out this inspection, it was necessary to destroy the part. We therefore decided to implement a non-contact measurement solution that could offer repeatability and simplicity of integration, "explains Lionel Marlier, Director of Security & Regulation at Faurecia Interior Systems.

The LJ-G is a 2D laser profilometer capable of performing on-the-fly measurements on production lines. The equipment consists of a controller, a monitor and laser heads, it is distinguished by its simplicity of setting. Its configuration menu allows unsuspecting users to configure the settings without difficulty. The software also facilitates control by a PC. The data is exported to a spreadsheet for analysis.

"The integration was very simple and the measurement remains stable without specific intervention on our part," added Lionel Marlier.

In the case of this control carried out at the factory, the skins may be of different colors: black, white or maroon. The LJ-G is not affected by the color and lighting conditions. This feature comes from the E3-CMOS image sensor, developed for industrial vision. It offers a dynamic range 300 times more extensive than traditional sensors. It can thus perform measurements on all surfaces regardless of color or reflectivity.

In addition, the LJ-G has a position-shifting function that allows stable measurements even when the targets are not properly positioned or tilted.

The LJ-G Series offers a repeatability of 1 micron with a sampling rate of 3.8 ms.

"Effectively, the control is twice as fast. It can be carried out in the production area, which improves our responsiveness, "explains Lionel Marlier.

"The implementation of the Keyence solution is part of a process of continuous quality improvement, but this automated measurement has also proved profitable. The control is no longer destructive, it is faster and requires less human intervention. Overall, we achieved a return on investment in less than a year while improving the accuracy of the measurement, "concludes Lionel Marlier.