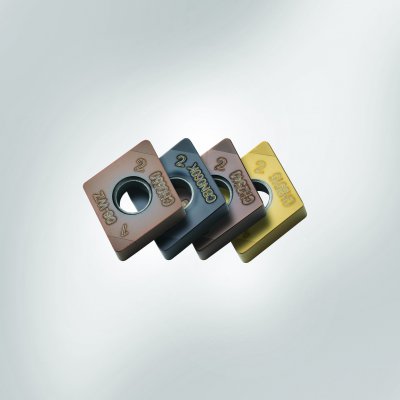

Seco has made significant advances in terms of hard turning operations with the introduction of its all new PCBN shades. Three shades are added to the Secomax CBN060K range to offer superior quality for the precision machining of hardened steels, allowing sharp, interrupted, shock-free machining.

The range now includes CH0550, CBN060K, CH2540 and CH3515 to cover a wide range of applications ranging from ISO H05 to H35. The shades use a bimodal substrate that maximizes hardness and wear resistance, thus providing high productivity and long tool life under varying machining conditions. They are ideally used in the automotive industry for components such as shafts, rings, constant velocity joints and gears that are integrated into gearboxes and transmissions of motorcycles, cars and trucks. They are also suitable for other fields such as the manufacture of ball bearing rings.

The CH0550 grade for ISO H05 is a completely new grade with a low CBN content designed for continuous cuts. It consists of a substrate containing 40% CBN and a brand new nanolamine coating (patented) whose Ti content is significantly higher than other TiAlN coatings. This gives it increased wear resistance in order to withstand crater wear and very high temperatures at high cutting speeds while generating excellent surface finishes.

The current grade CBN060K for ISO H15 is a hard grade used in continuous or slightly interrupted cutting operations at low to moderate cutting speeds. It also very well supports high advances. The CBN060K grade contains 60% CBN and incorporates a TiCN binder with metal superalloy additives. The patented nanolamine coating of TiAlN and TiSiN is exclusive to Seco.

With optimized edge preparations to extend the life of the tool, the new CH2540 for ISO H25 grade, which contains 65% CBN, is intended for interrupted cutting operations as well as for mixed operations Combining interrupted cuts and continuous cuts. Its substrate is based on the new shade technology with bimodal grain distribution, which improves wear resistance and allows it to withstand moderate to high cutting speeds. Examples of use: impact gears, shafts with keyway.

The shade CH3515 for ISO H35 is the most persistent shade of this new range of PCBN grades. Its use is recommended for machining hardened steel with strong interruptions. This grade, which contains 90% CBN with grain sizes of 2-4 ?m in an AlN binder, benefits from a TiAlN coating that improves the lifetime of the tool. This grade also gives excellent results in the field of powder metallurgy thanks to its high content of CBN and its high hardness.

The range now includes CH0550, CBN060K, CH2540 and CH3515 to cover a wide range of applications ranging from ISO H05 to H35. The shades use a bimodal substrate that maximizes hardness and wear resistance, thus providing high productivity and long tool life under varying machining conditions. They are ideally used in the automotive industry for components such as shafts, rings, constant velocity joints and gears that are integrated into gearboxes and transmissions of motorcycles, cars and trucks. They are also suitable for other fields such as the manufacture of ball bearing rings.

The CH0550 grade for ISO H05 is a completely new grade with a low CBN content designed for continuous cuts. It consists of a substrate containing 40% CBN and a brand new nanolamine coating (patented) whose Ti content is significantly higher than other TiAlN coatings. This gives it increased wear resistance in order to withstand crater wear and very high temperatures at high cutting speeds while generating excellent surface finishes.

The current grade CBN060K for ISO H15 is a hard grade used in continuous or slightly interrupted cutting operations at low to moderate cutting speeds. It also very well supports high advances. The CBN060K grade contains 60% CBN and incorporates a TiCN binder with metal superalloy additives. The patented nanolamine coating of TiAlN and TiSiN is exclusive to Seco.

With optimized edge preparations to extend the life of the tool, the new CH2540 for ISO H25 grade, which contains 65% CBN, is intended for interrupted cutting operations as well as for mixed operations Combining interrupted cuts and continuous cuts. Its substrate is based on the new shade technology with bimodal grain distribution, which improves wear resistance and allows it to withstand moderate to high cutting speeds. Examples of use: impact gears, shafts with keyway.

The shade CH3515 for ISO H35 is the most persistent shade of this new range of PCBN grades. Its use is recommended for machining hardened steel with strong interruptions. This grade, which contains 90% CBN with grain sizes of 2-4 ?m in an AlN binder, benefits from a TiAlN coating that improves the lifetime of the tool. This grade also gives excellent results in the field of powder metallurgy thanks to its high content of CBN and its high hardness.